HYDRAULIC / PNEUMATIC DRIVES

We offer various pneumatic and hydraulic solutions for the drive for the needle stroke in valve gate systems. Each solution has its strengths, depending on the available space and set priority.

We offer various pneumatic and hydraulic solutions for the drive for the needle stroke in valve gate systems. Each solution has its strengths, depending on the available space and set priority.

The NK drive unit is screwed to the rear of the hot runner manifold. The unit can be operated pneumatically and hydraulically. The seal sets within the unit are similarly designed for both media. For example, pneumatics can be connected during the sampling by the machine manufacturer and later in the serial production of hydraulics. Due to the mounting on the hot runner manifold, the drive units are equipped with water cooling, which ensures the longevity of the drives.

The needle position can be adjusted externally using the clamping plate. A corresponding hold in the clamping plate as well as a possible heat insulation plate must be provided for this.

Especially in combination with DS nozzles it is thus possible to create completely pre-wired, screw-fitted systems which can be handled as a component.

The NT drive unit is installed in the clamping plate and can optionally drive individual needles within the system or, combined with several NT units, drive a complete lifting plate.

The unit can be operated pneumatically and hydraulically. The seal sets within the unit are similarly designed for both media. For example, pneumatics can be connected during the sampling by the machine manufacturer and later in the serial production of hydraulics.

The needle position can be adjusted externally using the clamping plate.

The valve gates can be decoupled from the drive cylinders for maintenance work, making it possible to disassemble the clamping plate without previously disassembling the valve gates from the hot runner system.

The cylinders do not require their own cooling, however the clamping plate is provided with a temperature control circuit.

Particularly in the case of high-speed systems, operation by means of lifting plate has the advantage that only a few drive cylinders are required and thus a small installation space suffices. The lifting plate also ensures that all valve gate nozzles are opened and closed absolutely synchronously. The drive is operated by hydraulic / pneumatic cylinders mounted on the side of the tools, or with NT units in the clamping plate.

Continuous development and the passion to innovate is our incentive.

- Martin Hallenberger, Head of construction department

Many requirements are often fulfilled by the drive. The distances between the drives must be narrow for implementing the position of the injection points, necessary sequential valve gate controls must be feasible, specifications of your customer regarding media selection, small installation spaces due to cooling and tool functions, etc.

Contact us and we will be happy to advise you on the appropriate drive type for your application.

Please use the filter options and then click on the nozzle according to your selection in the preview window on the right side.

Reset all filter

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Single application

Note:

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Single application

Note:

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Single application

Note:

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240

Application:

Single application

Note:

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240

Application:

Single application

Note:

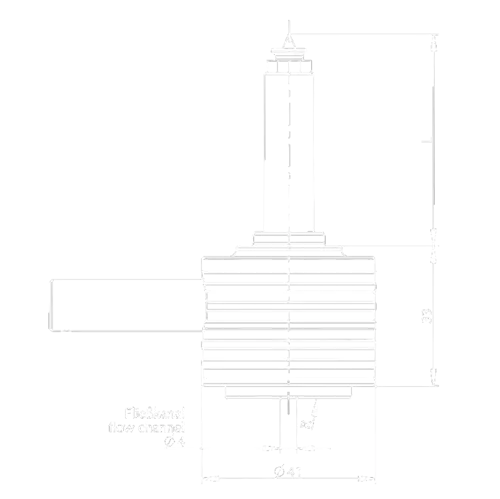

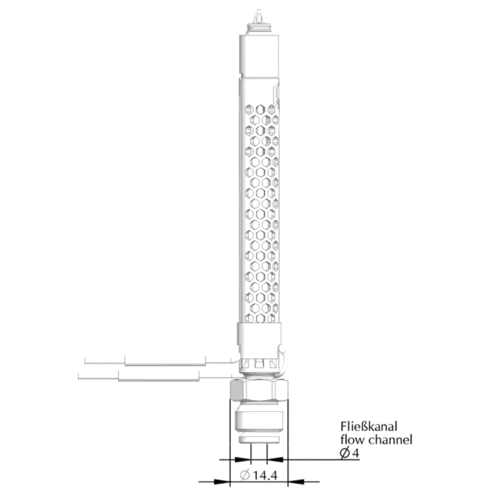

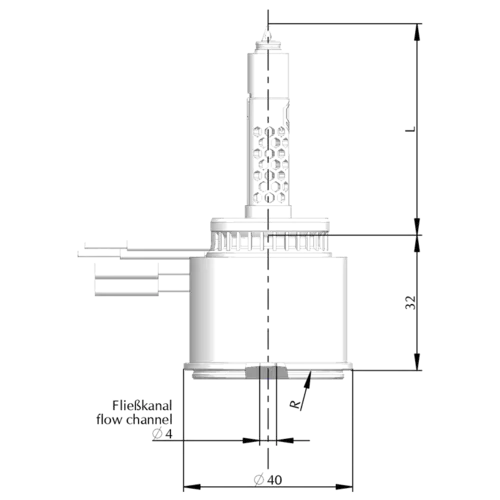

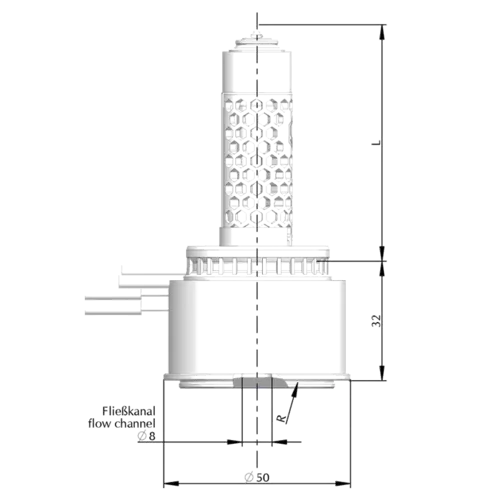

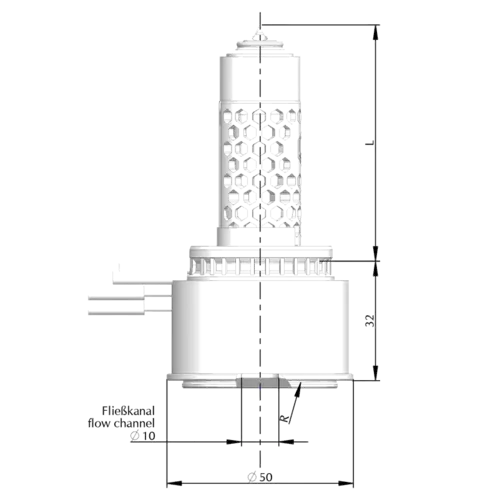

For use with manifold systems in cramped installation situations.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100

Application:

Multiple applications (system application)

Note:

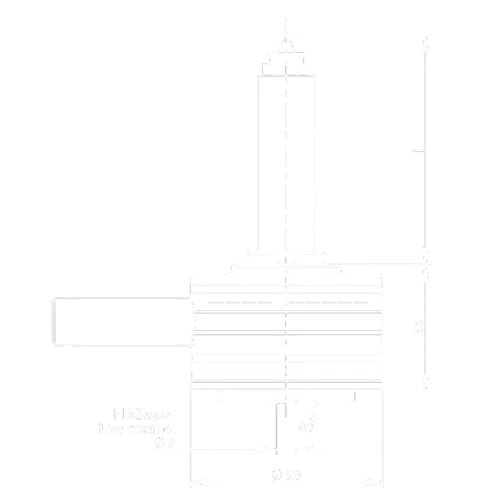

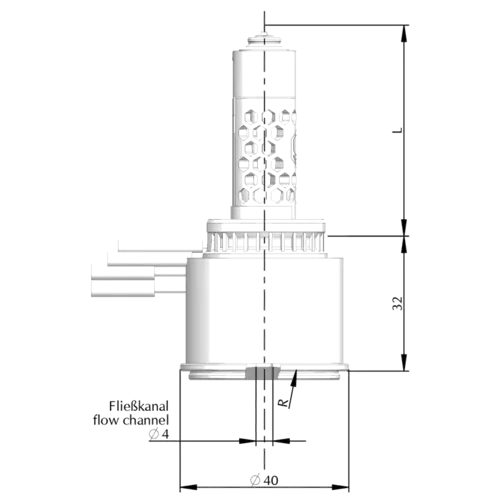

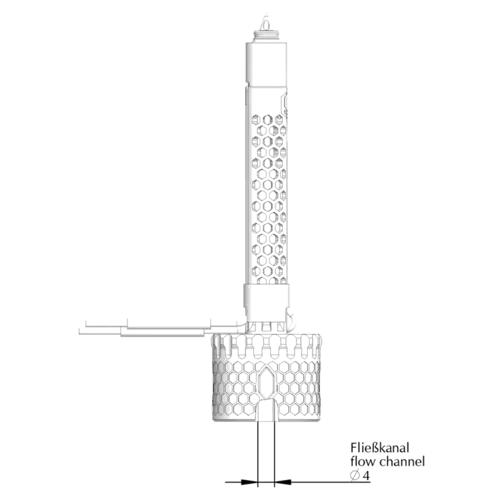

For use with manifold systems in cramped installation situations.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, POM, PP, PS, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100

Application:

Multiple applications (system application)

Note:

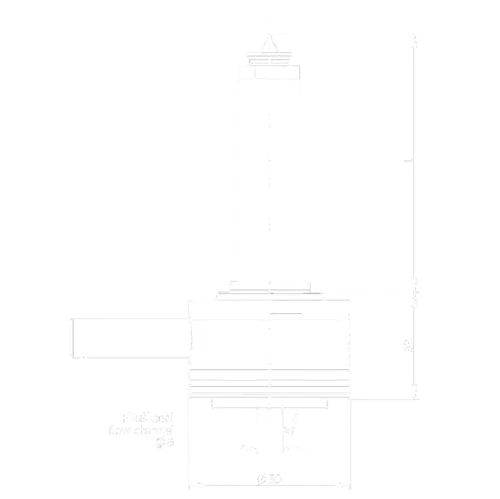

System nozzle available with all tip variants.

Sealent type:

Valve gate tip seal

Spitzentyp:

Torpedo, EVO-RS tip, through-hole tip, Open tip

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE,POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

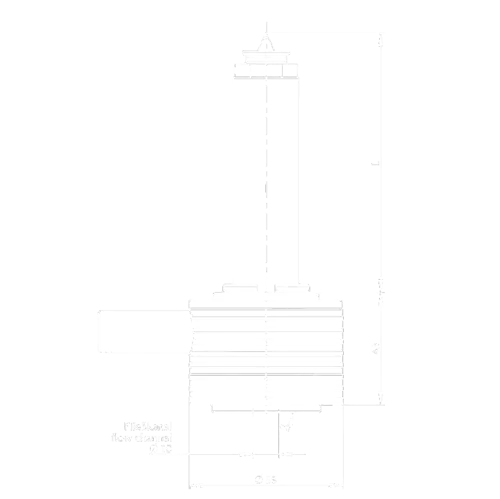

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE,POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available with all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PMMA, POM, PP, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS ,ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

System nozzle available in many tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, PA6, PA6.6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

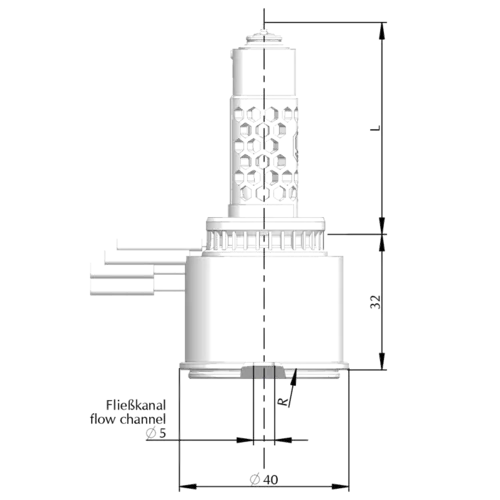

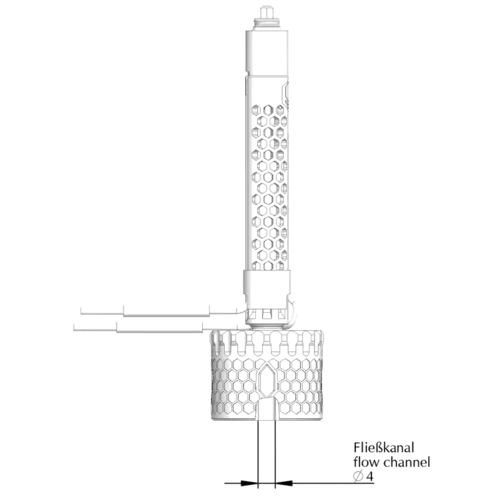

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PMMA, POM, PP, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN,SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA4.6, PA 4.6 GF15, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6 GF15, PA6 GF30, PA6.6, PA4.6, PBT, PBT GF15, PBT GF30, PC, PC/ABS, PE, PMMA, POM, PP, PP GF15, PP GF30, PPS, PPS + 40%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA4.6, PA 4.6 GF15, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PMMA, POM, PP, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA4.6, PA 4.6 GF15, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PC, PC/ABS, PE, PMMA, PP, PP GF15, PP GF30, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6 GF15, PA6 GF30, PC, PC/ABS, PE, PMMA, PP, PP GF15, PP GF30, PPSU, PS, SAN, SB

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCT, PCTA, PCTG, PETG, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCT, PCTA, PCTG, PETG, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note: