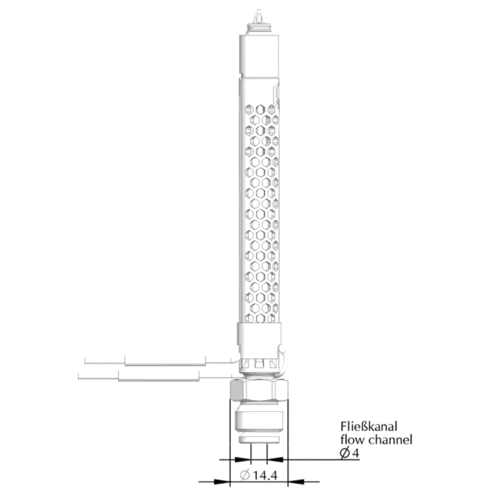

LATERAL INJECTION LINEAR SYSTEM

Our standard linear system is suitable for lateral connection. The standard linear system is characterized by:

Our standard linear system is suitable for lateral connection. The standard linear system is characterized by:

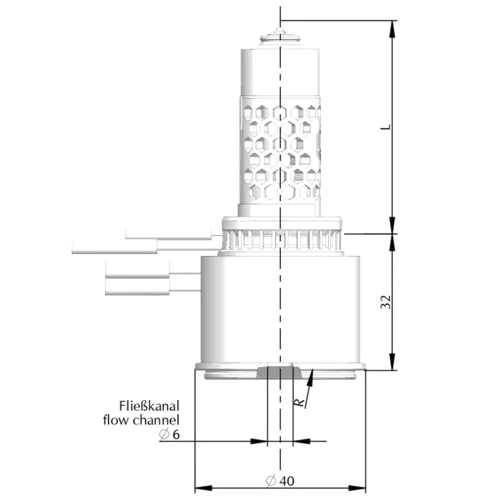

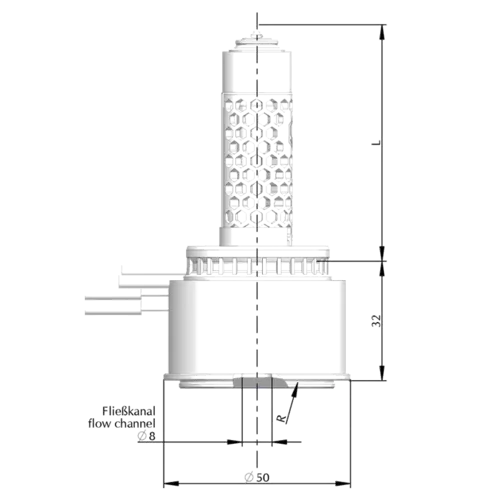

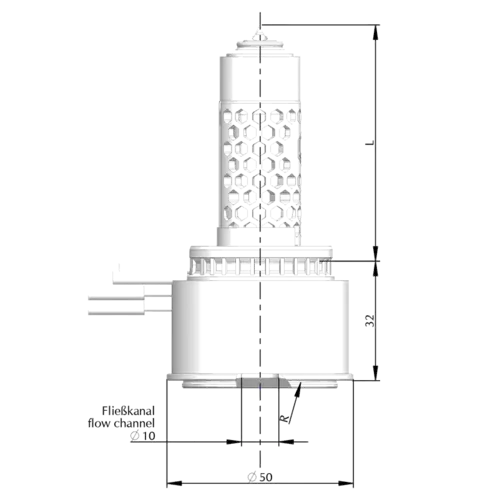

The nozzles are screwed to the distributor and is leakproof. Nevertheless, short nozzles can also be implemented due to the intelligent system structure. The system is therefore very easy to install and easy to use.

Using the integrated 230V heater and the defined sensor position, homogeneous temperature control is achieved across the entire nozzle length. A complete system nozzle with perfect control behavior is available for each injection point.

The nozzles can be delivered with a tip seal.

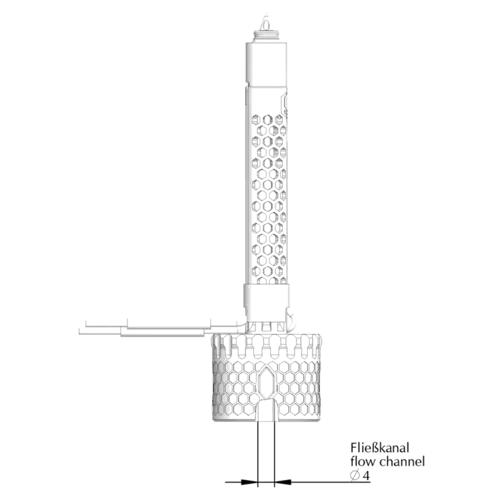

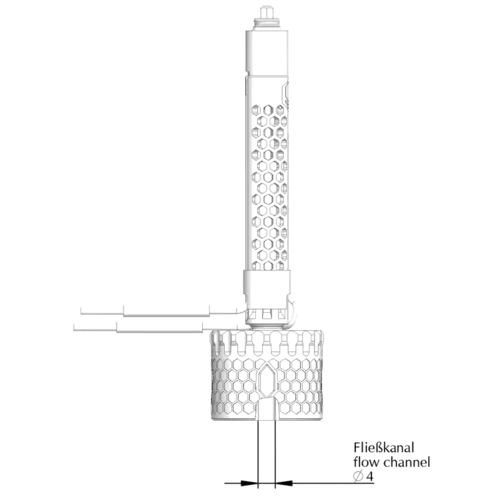

With the “B” version, the necessary installation space of the nozzles can be reduced again, allowing them to be used in the smallest installation space.

Due to the modular methodology, all standard nozzles as well as their replacement and spare parts can be delivered in the shortest possible time.

The minimal surface area of the injection mold and the use of high-tech alloys ensure that almost no heat is released to the injection mold. This guarantees short cycle times and high productivity.

Passion for Plastics.

- Sales team

The nozzle is the alpha and omega of every hot runner system. It decides the product quality of a hot runner system with regard to filling, vestige and practicality.Due to its modular system construction, the nozzle is optimally combined for your application from the various possibilities.

NOZZLE TIPS

There are various nozzle tips to choose from

SUBJECT NUMBERS

All systems have paired nozzle arrangements, thus 2-cavity| 4-cavity | 8-cavity | 16-cavity| 32-cavity | 64-cavity | 128-cavity systems possible.

HOT HALVES

We are happy to deliver the linear system as a hot half with complete wiring and coordination of the mold structure.

Please use the filter options and then click on the nozzle according to your selection in the preview window on the right side.

Reset all filter

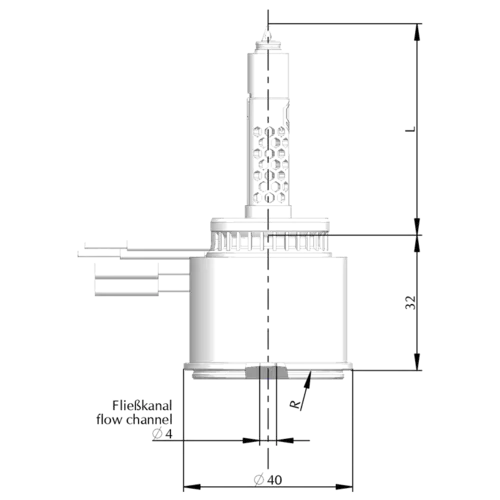

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Single application

Note:

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Single application

Note:

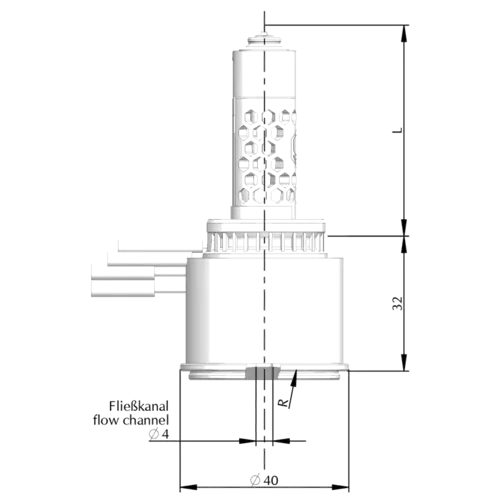

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Single application

Note:

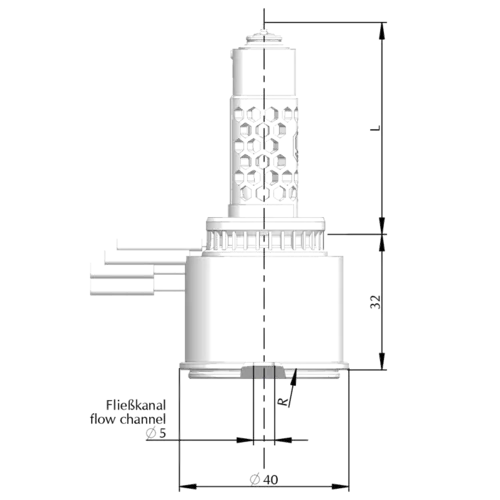

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240

Application:

Single application

Note:

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240

Application:

Single application

Note:

For use with manifold systems in cramped installation situations.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100

Application:

Multiple applications (system application)

Note:

For use with manifold systems in cramped installation situations.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, POM, PP, PS, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100

Application:

Multiple applications (system application)

Note:

System nozzle available with all tip variants.

Sealent type:

Valve gate tip seal

Spitzentyp:

Torpedo, EVO-RS tip, through-hole tip, Open tip

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE,POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE,POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available with all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PMMA, POM, PP, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS ,ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

System nozzle available in many tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, PA6, PA6.6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120

Application:

Multiple applications (system application)

Note:

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PMMA, POM, PP, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN,SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

Attention:

New O-rings should be used each time of disassembly.

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA4.6, PA 4.6 GF15, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6 GF15, PA6 GF30, PA6.6, PA4.6, PBT, PBT GF15, PBT GF30, PC, PC/ABS, PE, PMMA, POM, PP, PP GF15, PP GF30, PPS, PPS + 40%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA4.6, PA 4.6 GF15, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PMMA, POM, PP, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA4.6, PA 4.6 GF15, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Single application

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PC, PC/ABS, PE, PMMA, PP, PP GF15, PP GF30, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6 GF15, PA6 GF30, PC, PC/ABS, PE, PMMA, PP, PP GF15, PP GF30, PPSU, PS, SAN, SB

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCT, PCTA, PCTG, PETG, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCT, PCTA, PCTG, PETG, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note: