Please use the filter options and then click on the nozzle according to your selection in the preview window on the right side.

Reset all filter

- hot halves

- manifold system

- single nozzle

- floating

- screwed

- open

- valve gate nozzle

- ABS

- ASA

- Copolyester

- LCP

- PA4.6

- PA4.6 GF15

- PA4.6 GF30

- PA4.6 GF50

- PA6

- PA6 GF15

- PA6 GF30

- PA6 GF50

- PA6.6

- PA6.6 GF15

- PA6.6 GF30

- PA6.6 GF50

- PBT

- PBT GF15

- PBT GF30

- PBT GF50

- PC

- PC/ABS

- PCT

- PCTA

- PCTG

- PE

- PEEK

- PET

- PETG

- PMMA

- POM

- PP

- PP GF15

- PP GF30

- PPO

- PPS

- PPS +40%

- PPS +60%

- PPSU

- PS

- SAN

- SB

- TPE

- TPU

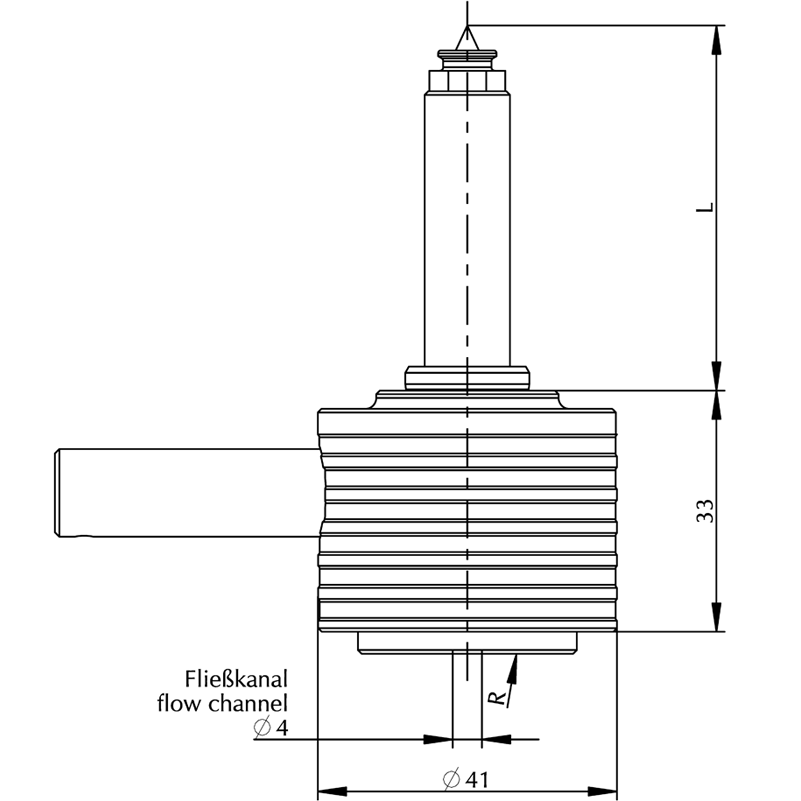

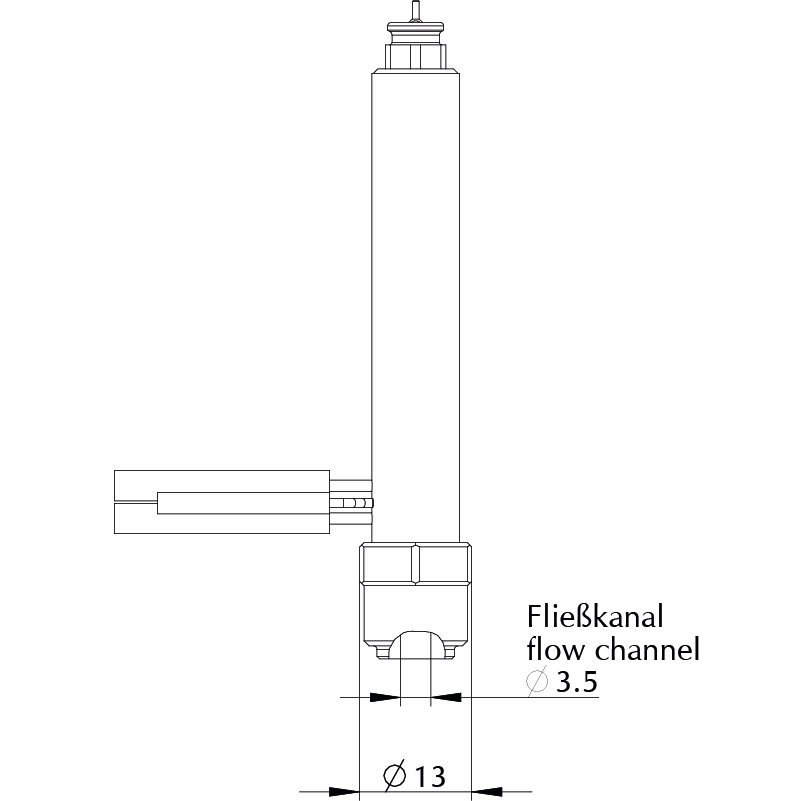

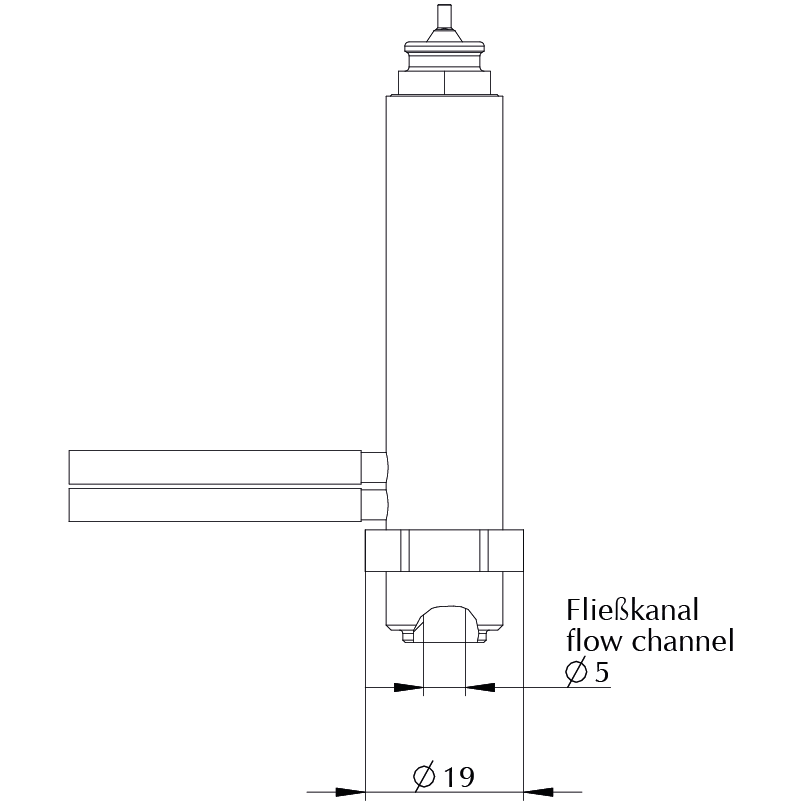

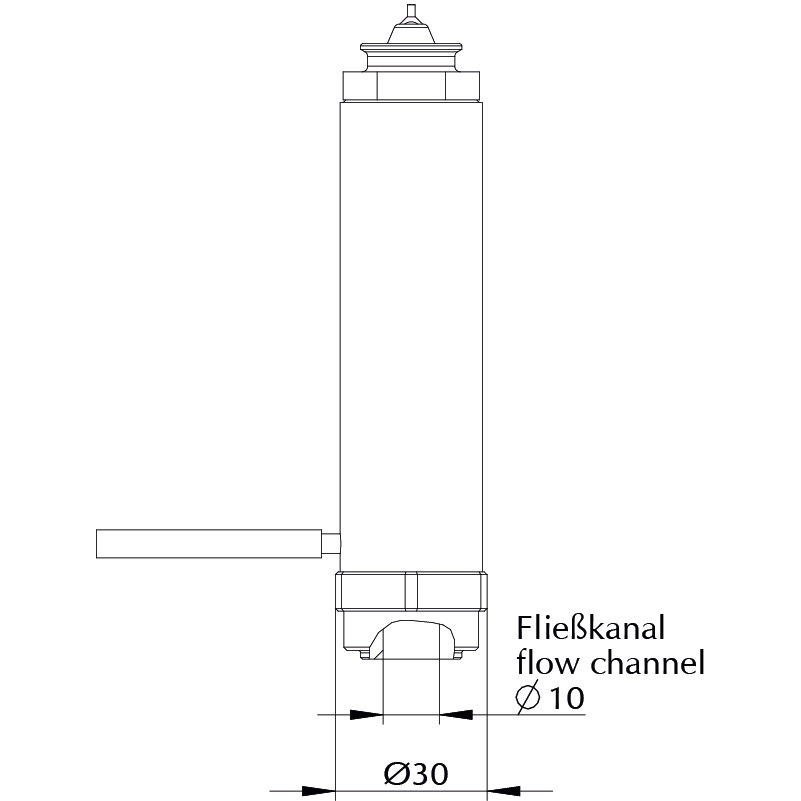

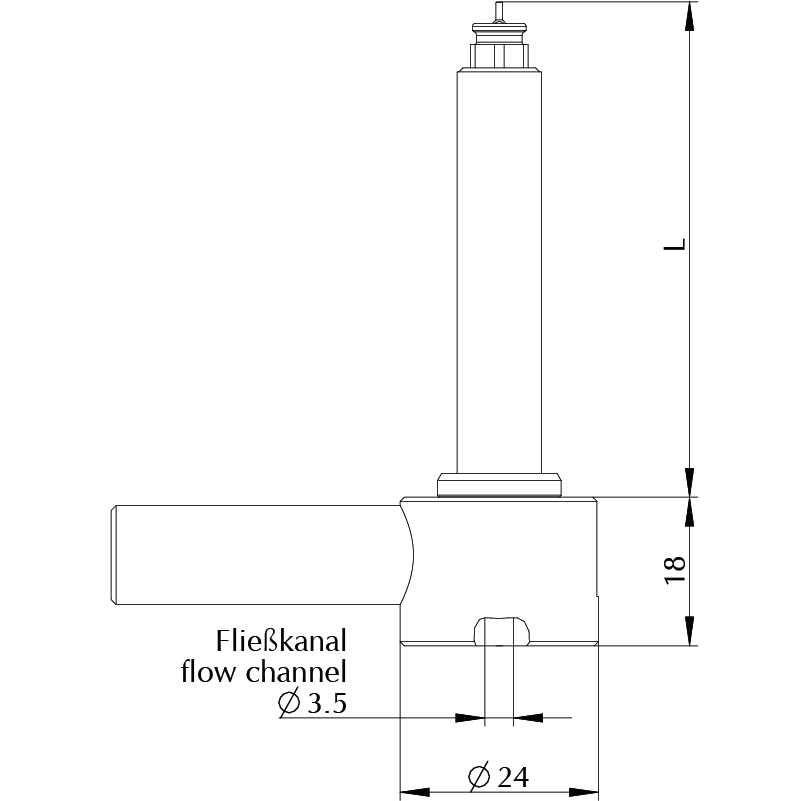

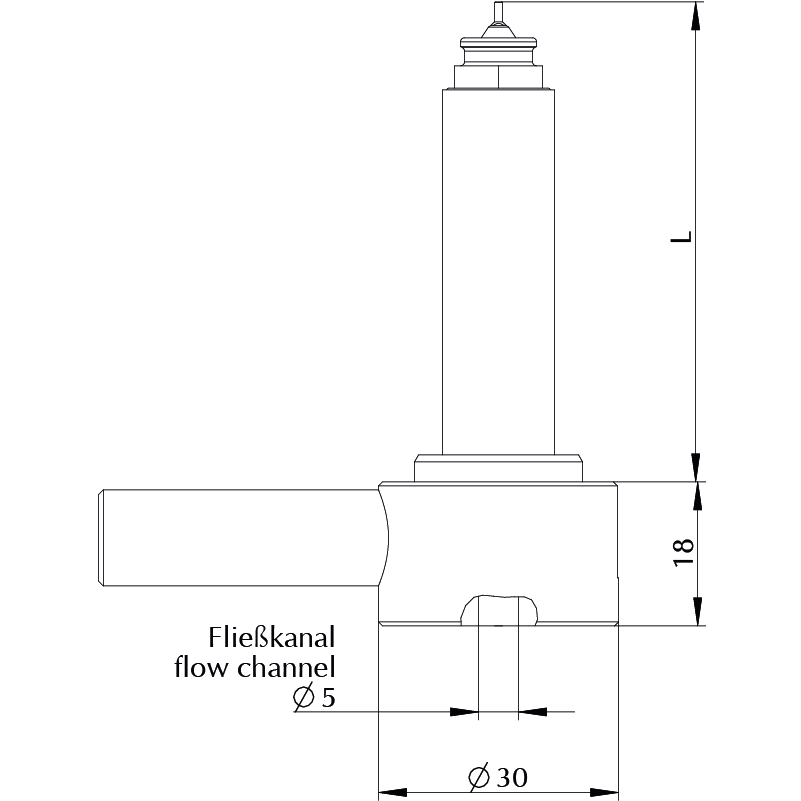

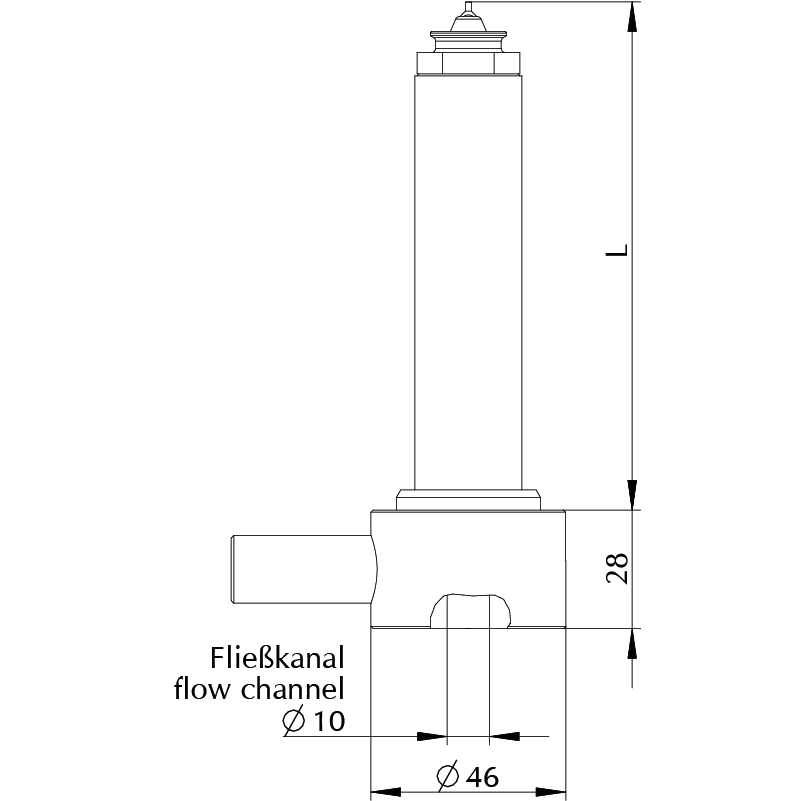

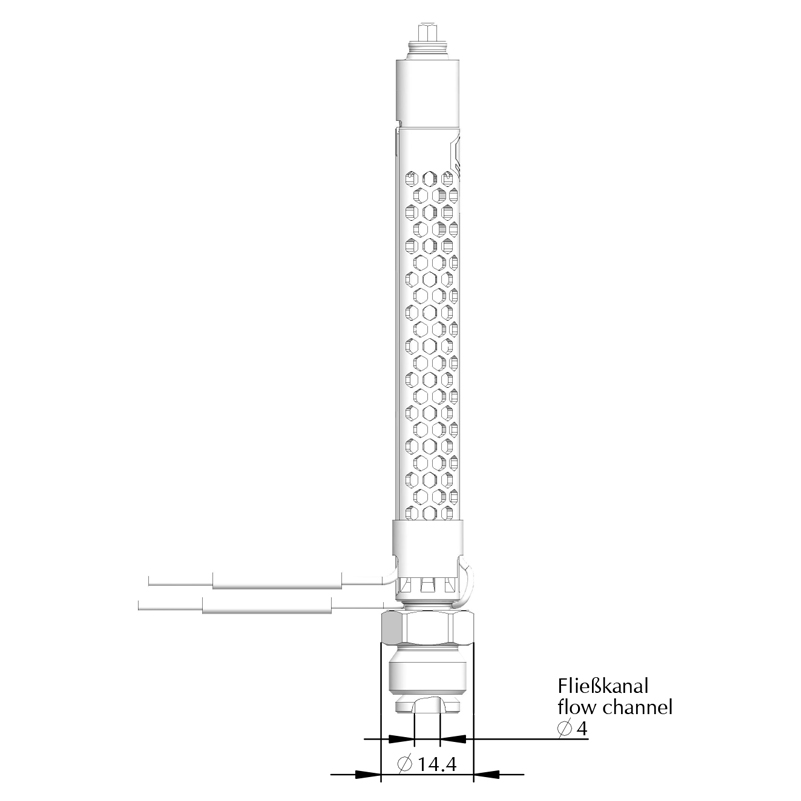

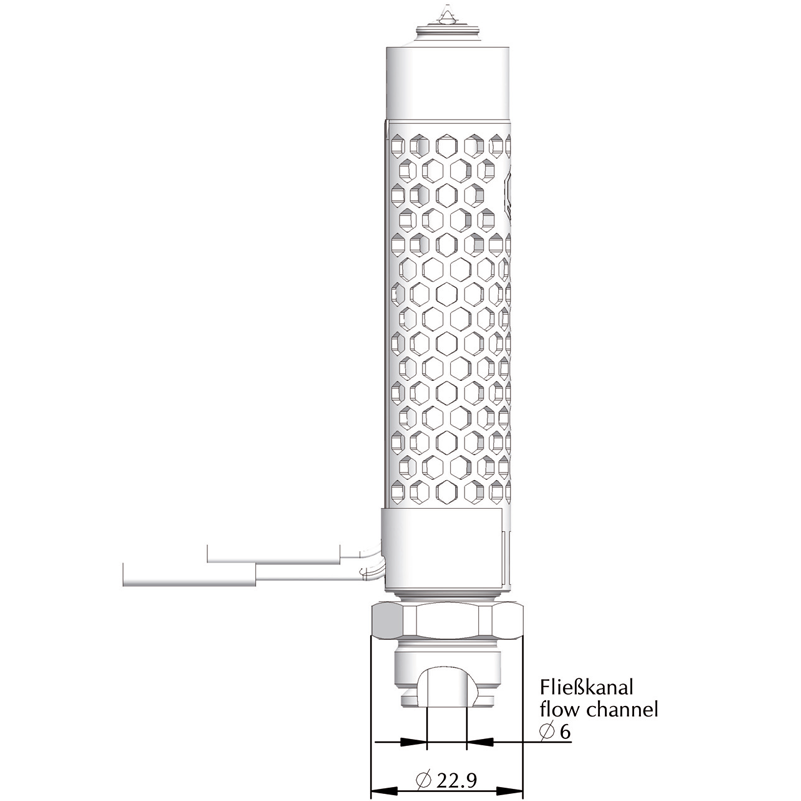

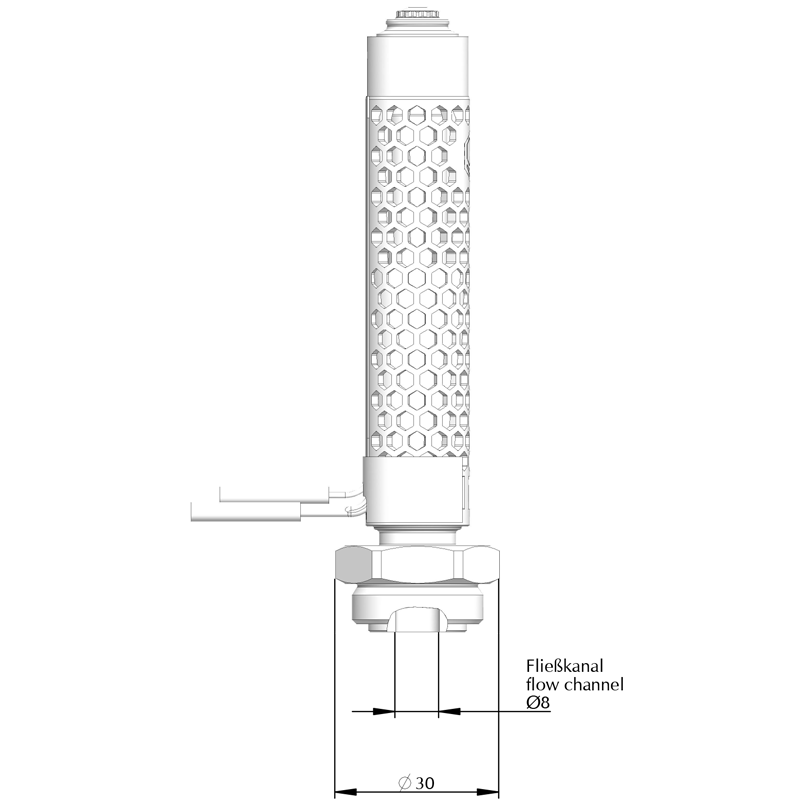

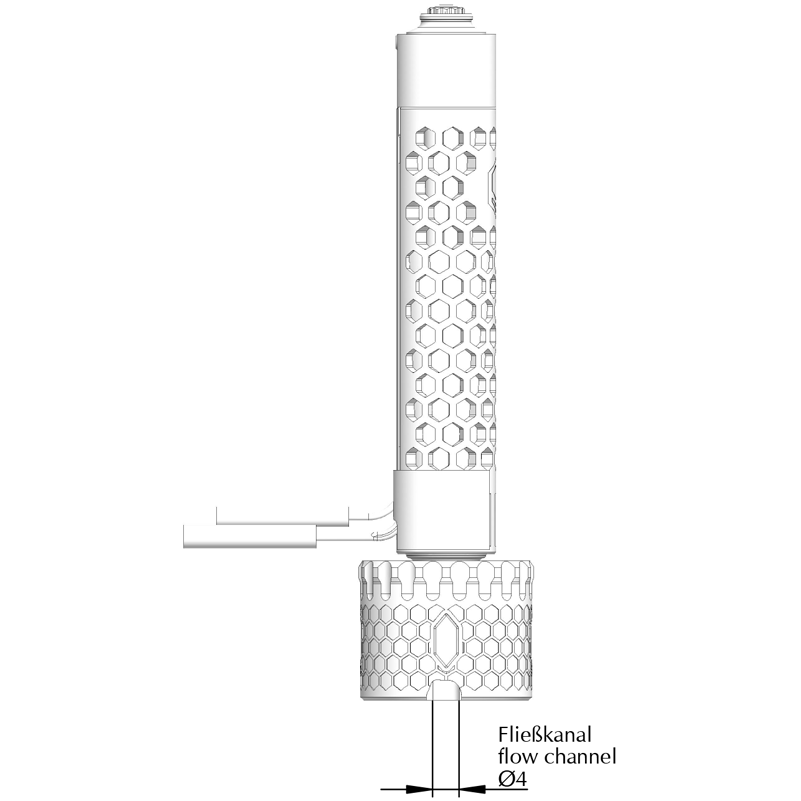

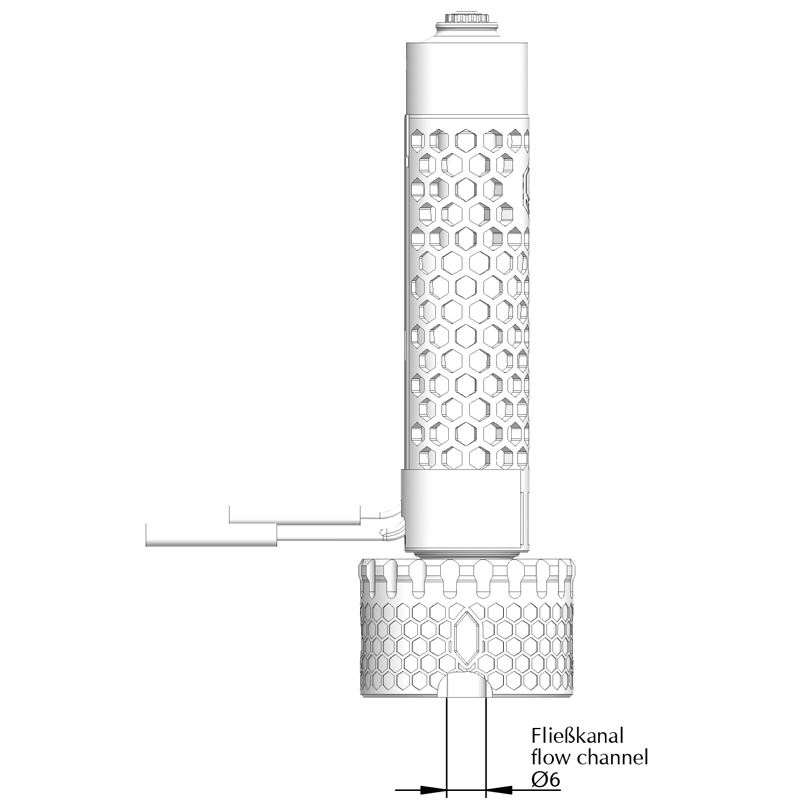

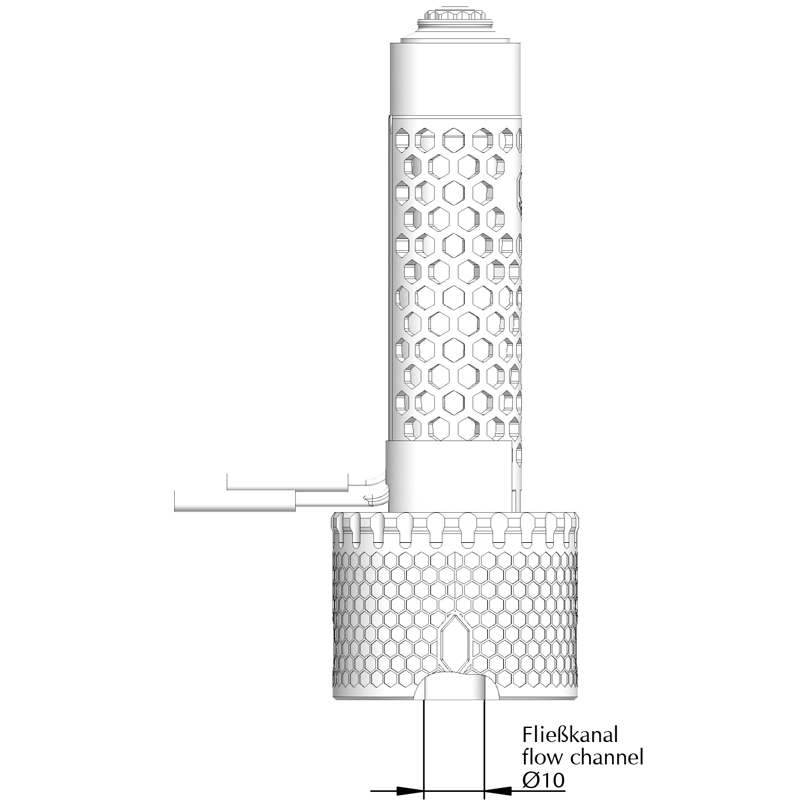

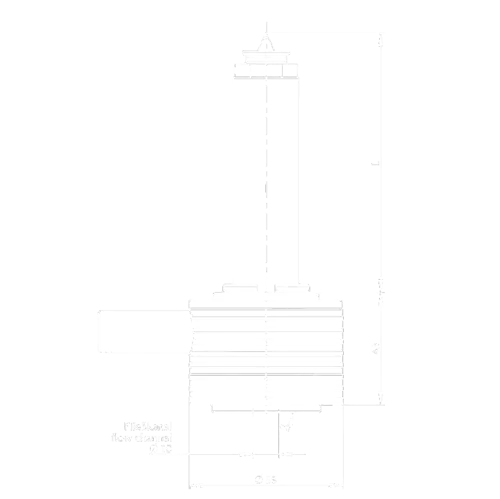

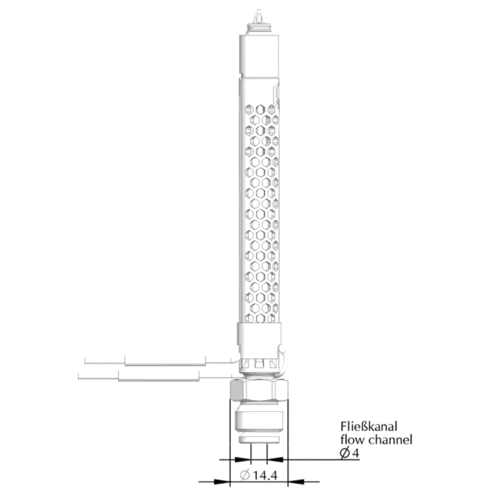

DB-16-R

DB-16-R

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

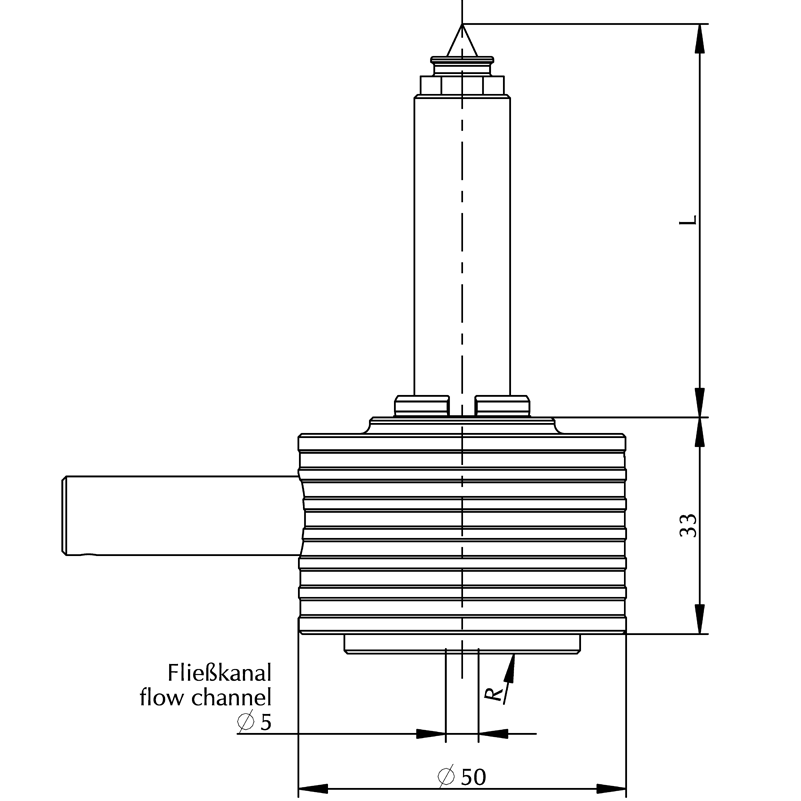

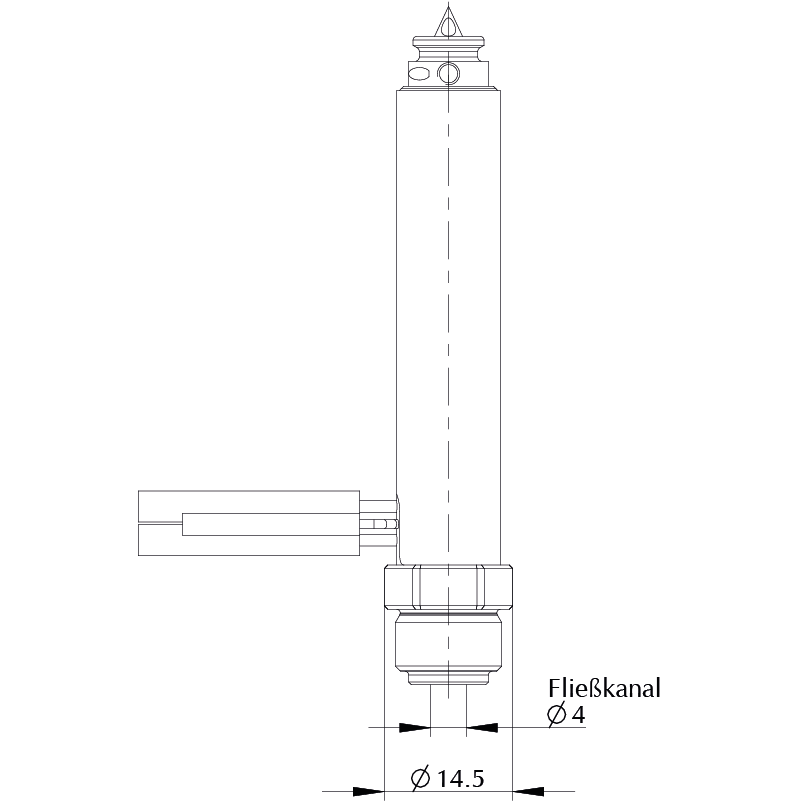

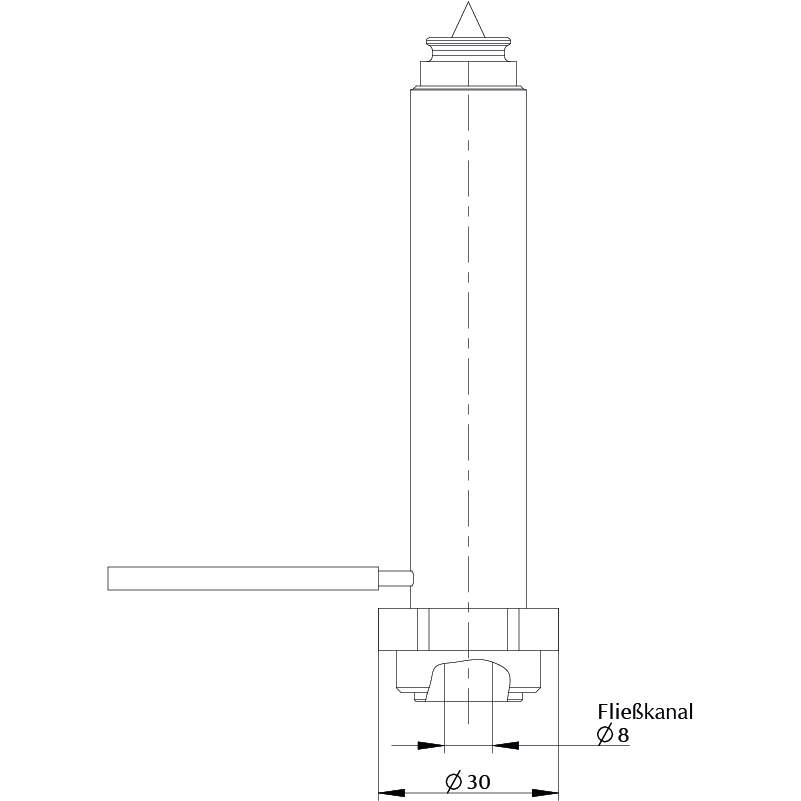

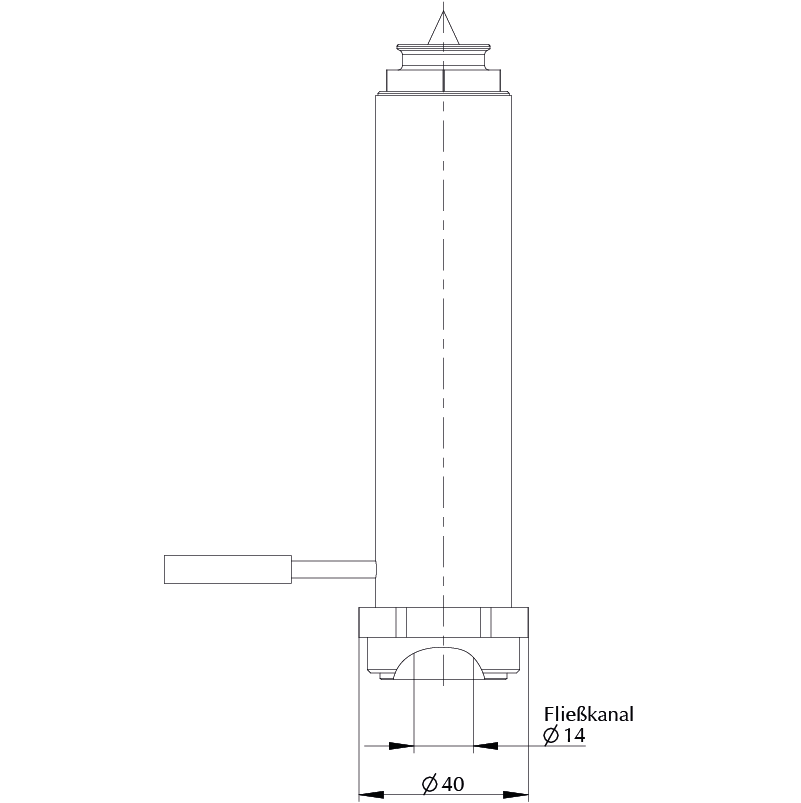

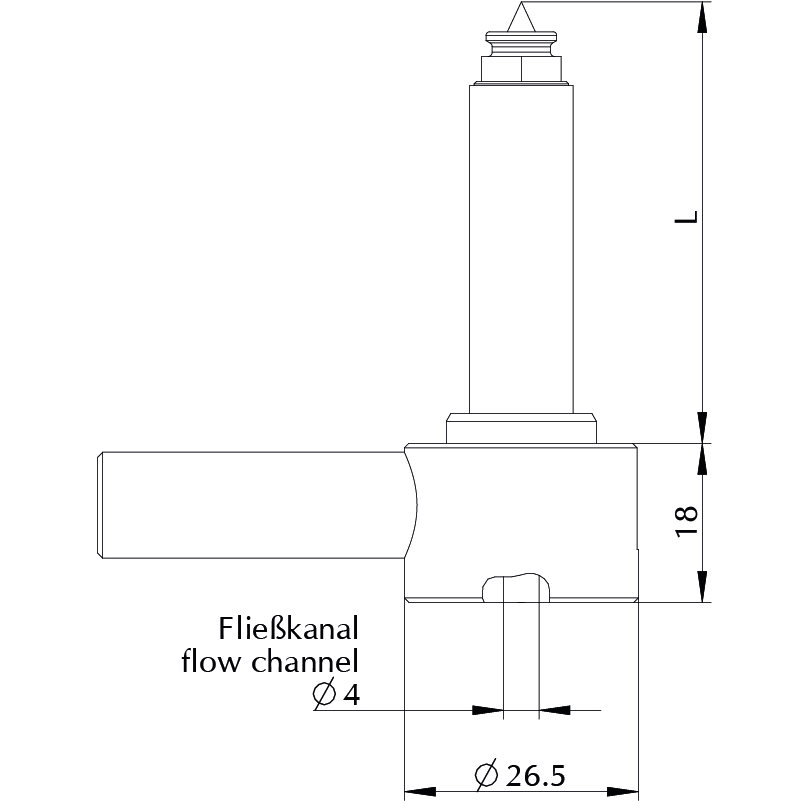

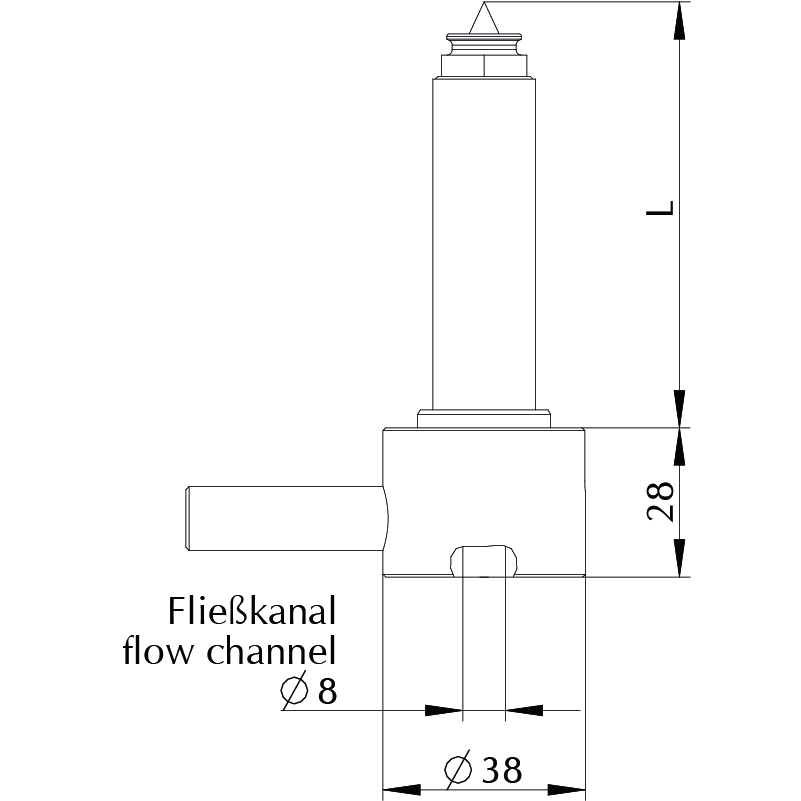

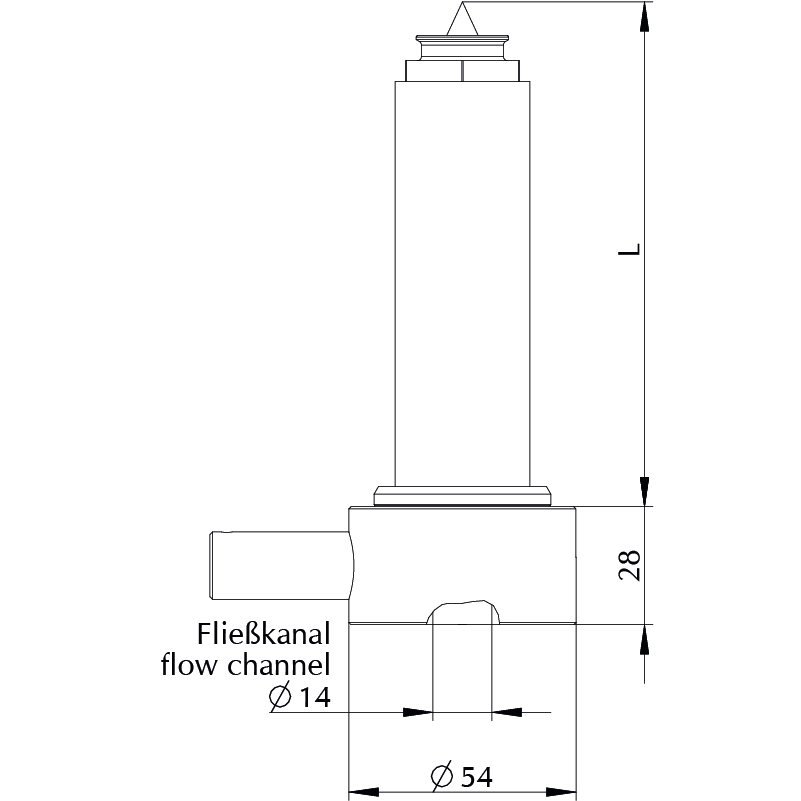

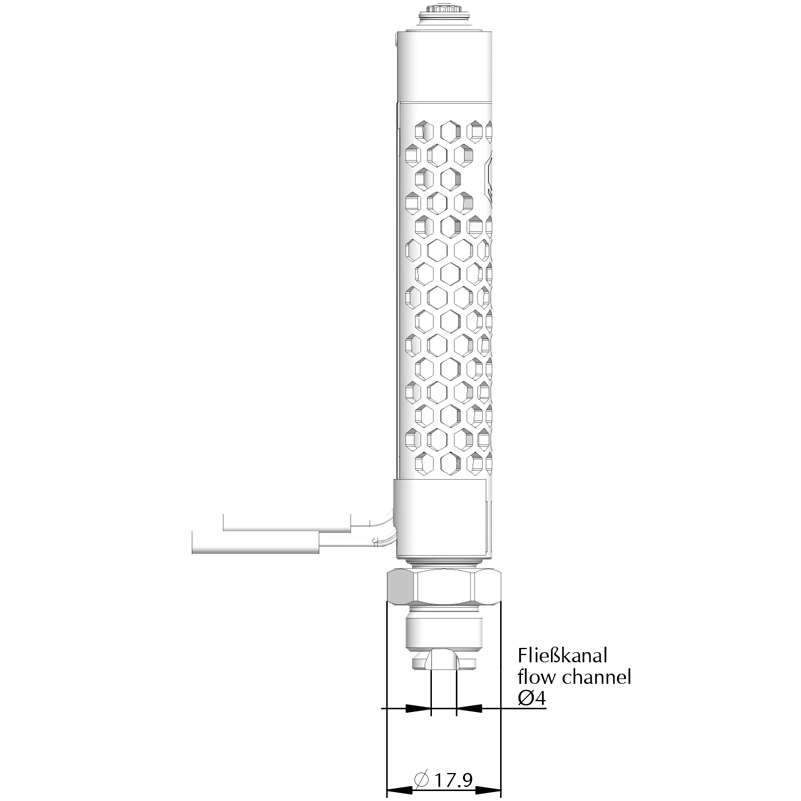

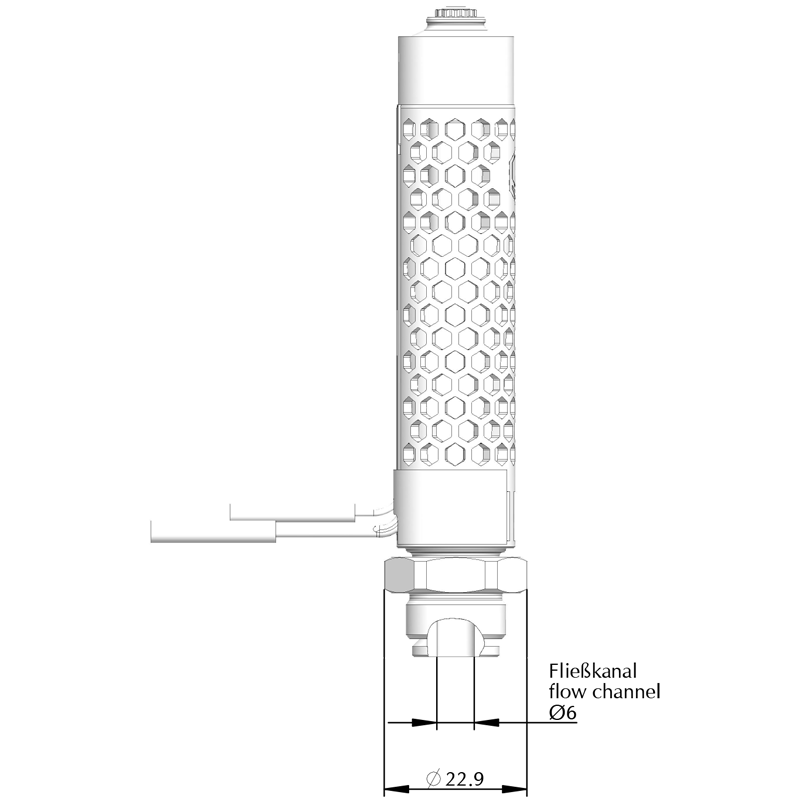

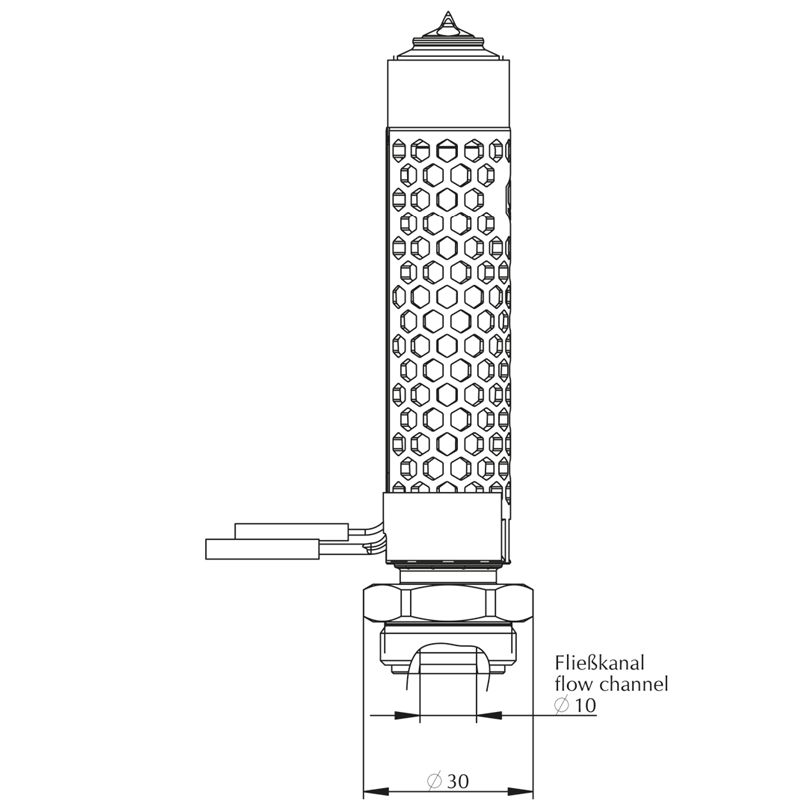

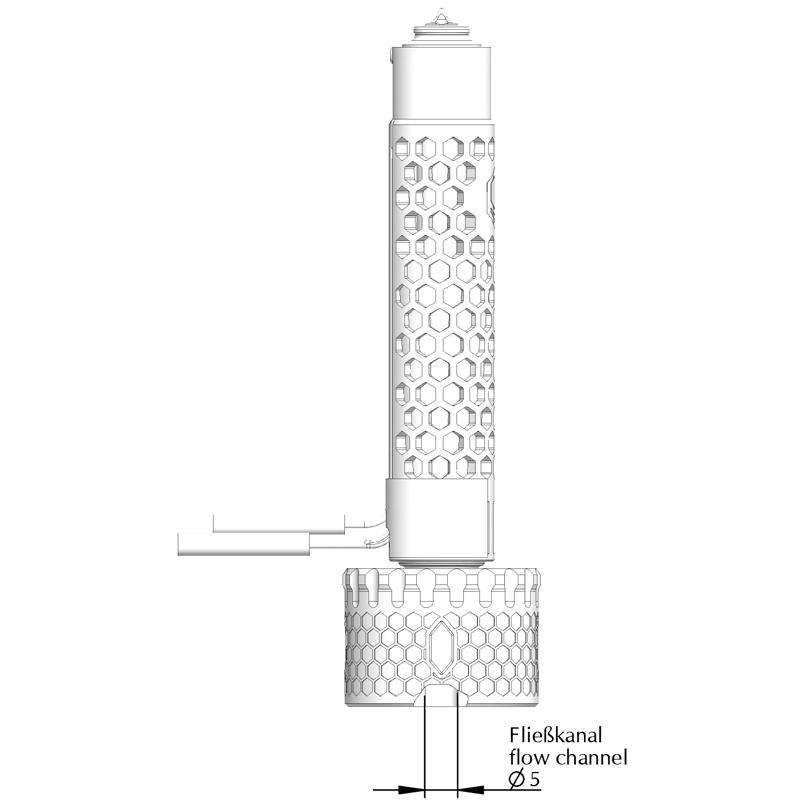

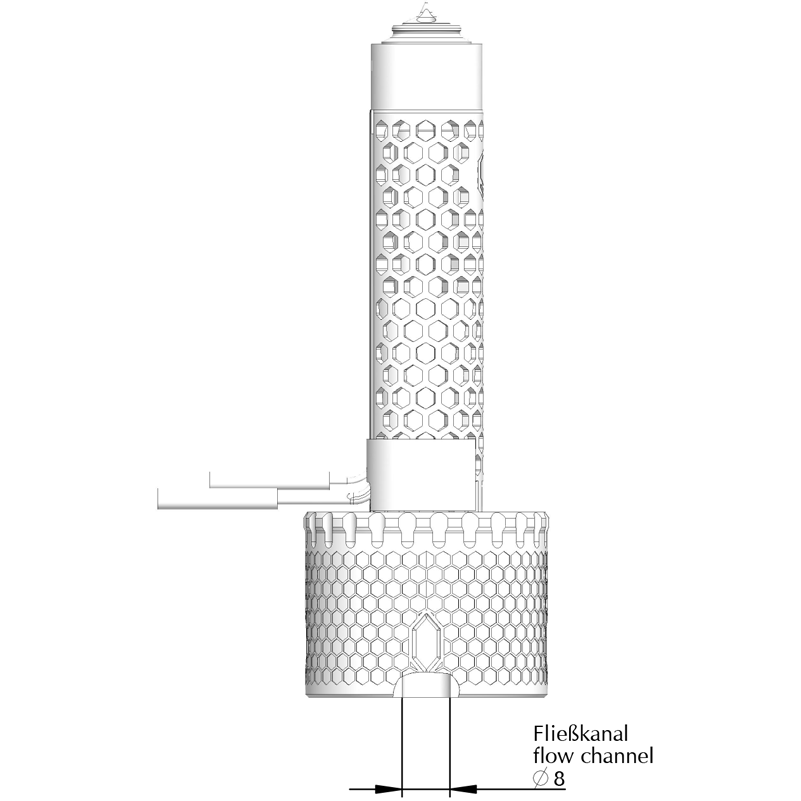

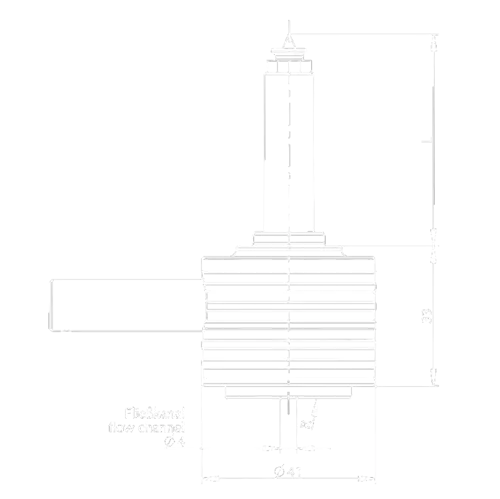

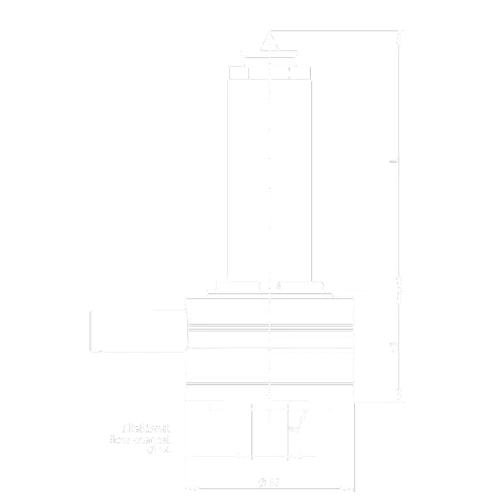

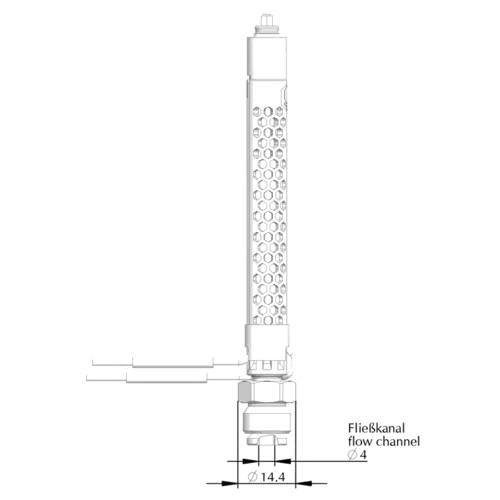

DB-20-R

DB-20-R

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

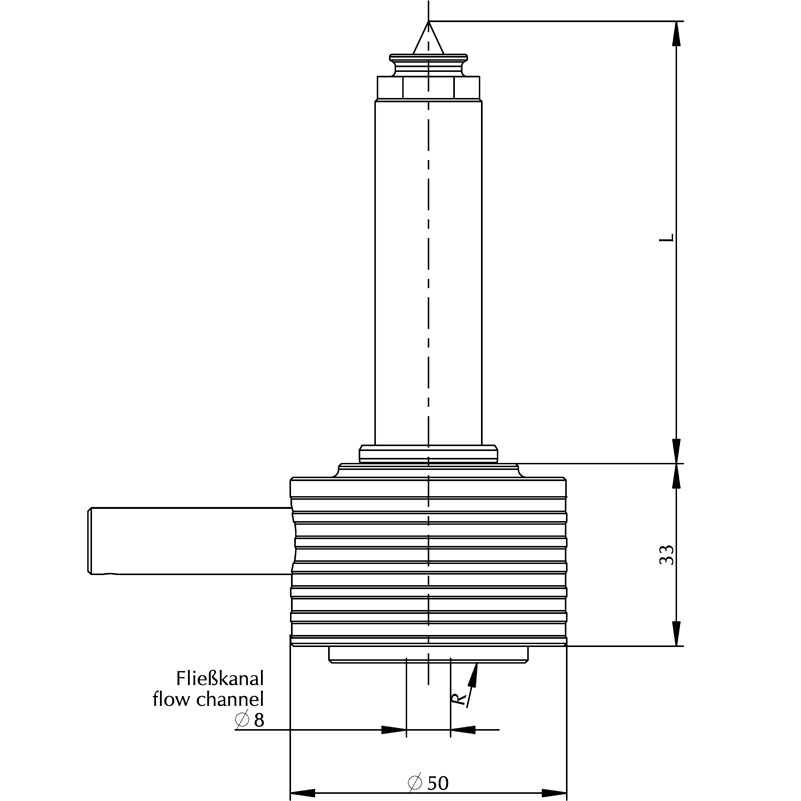

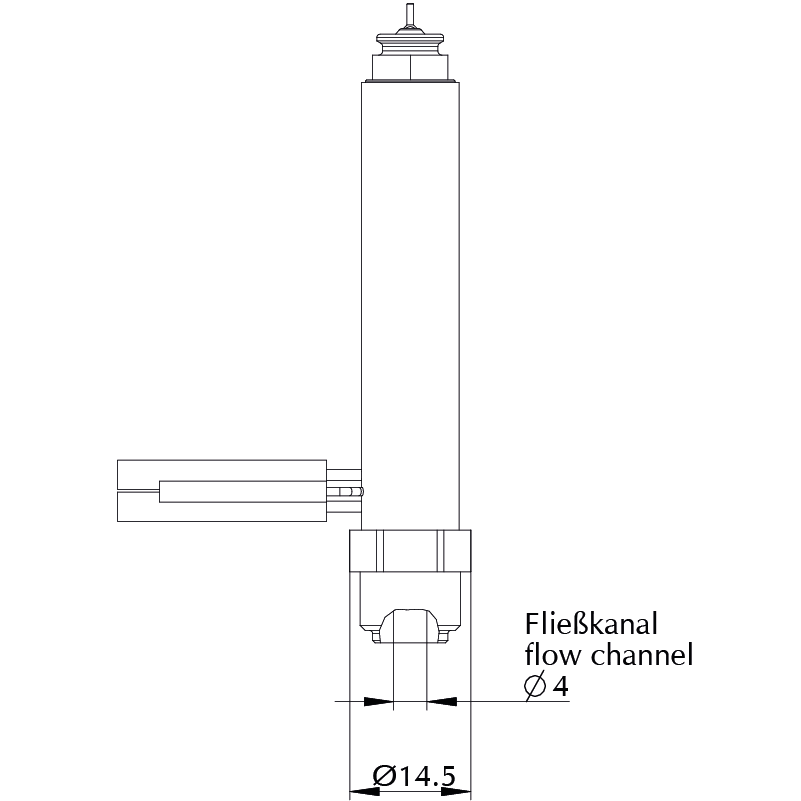

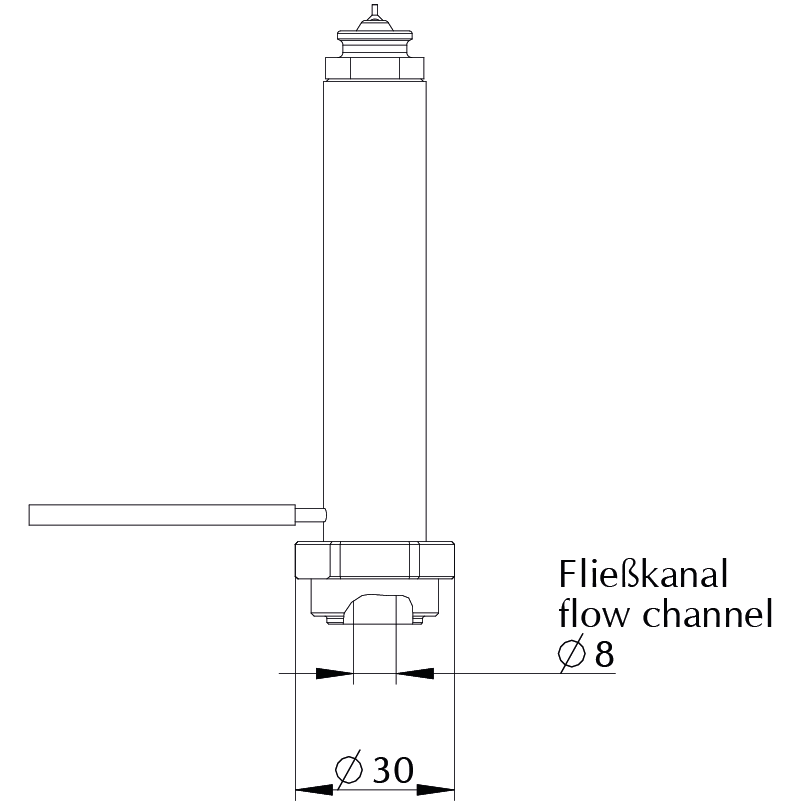

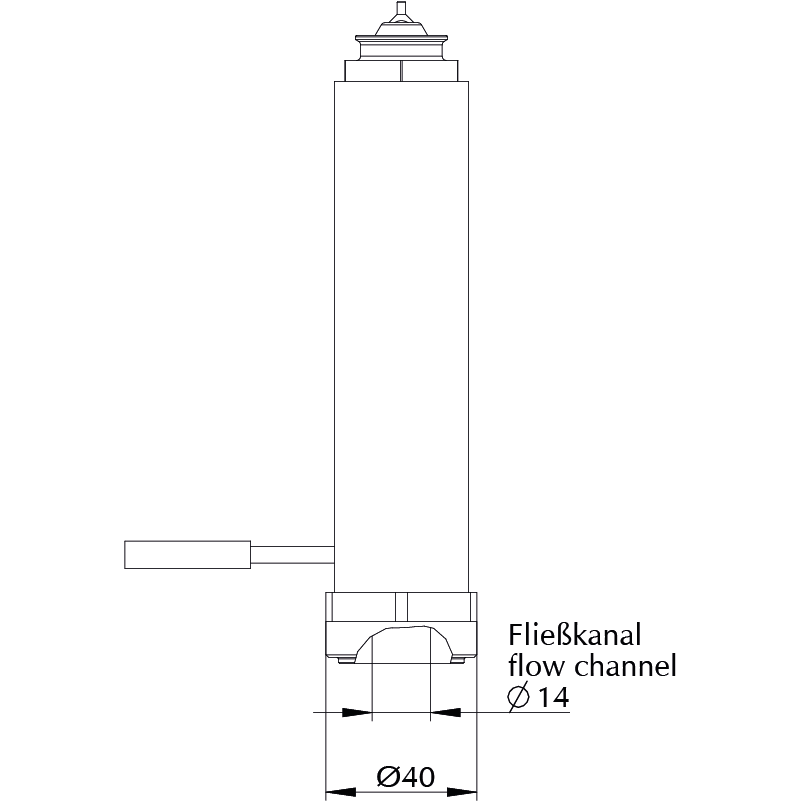

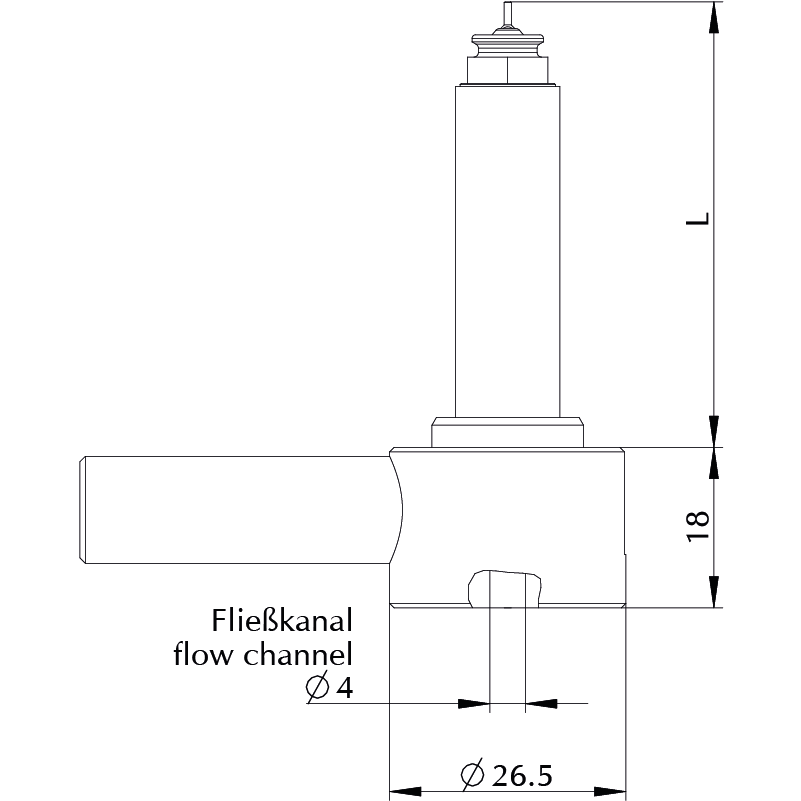

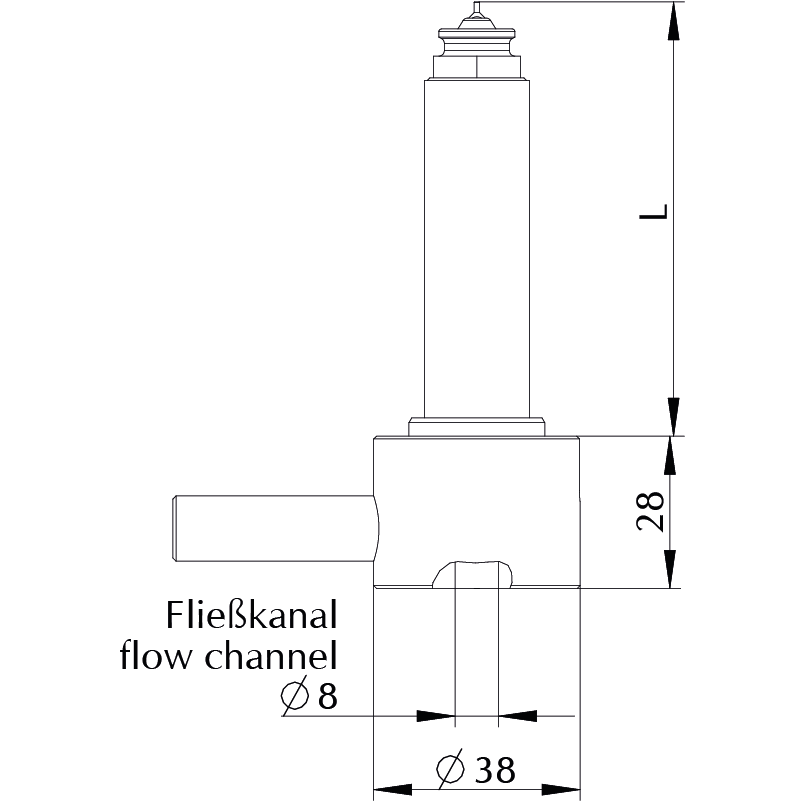

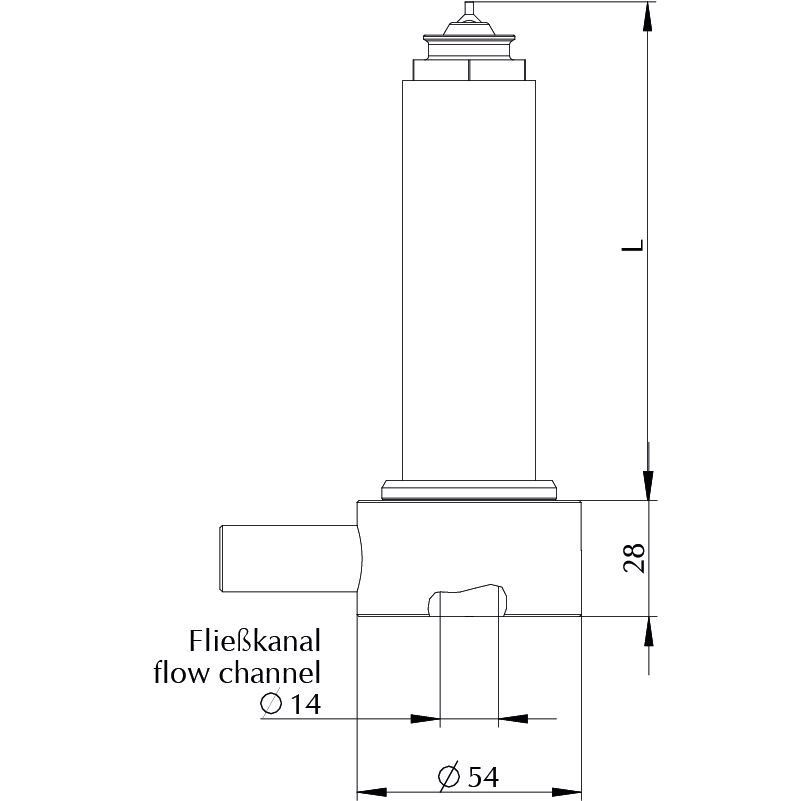

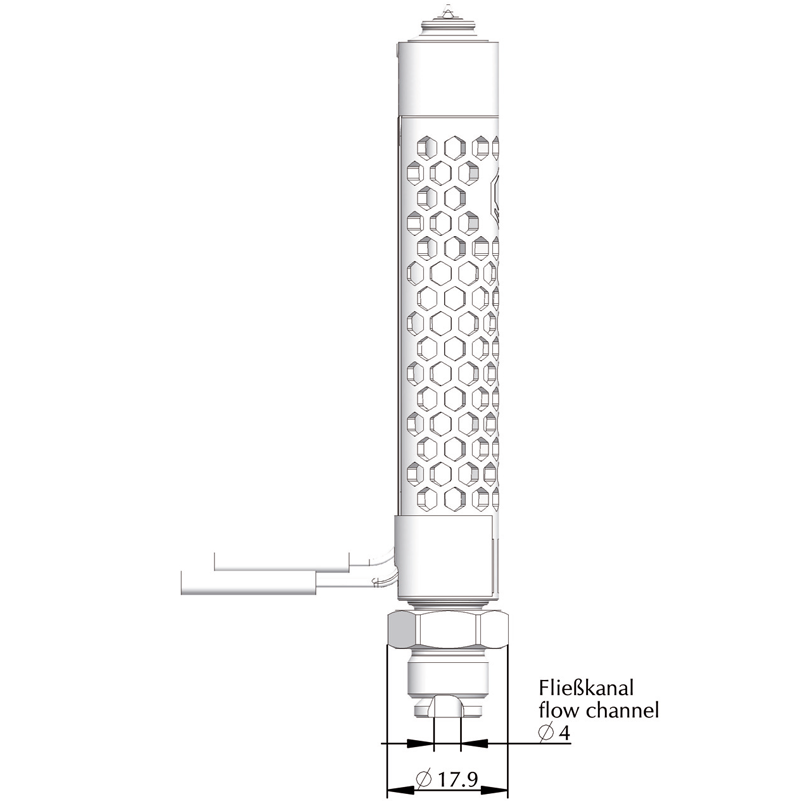

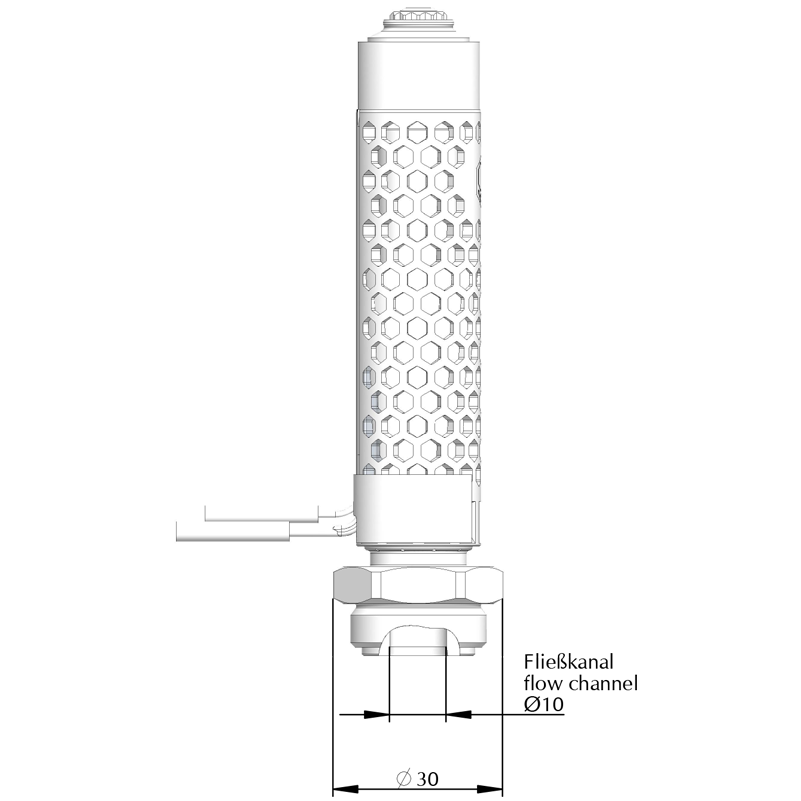

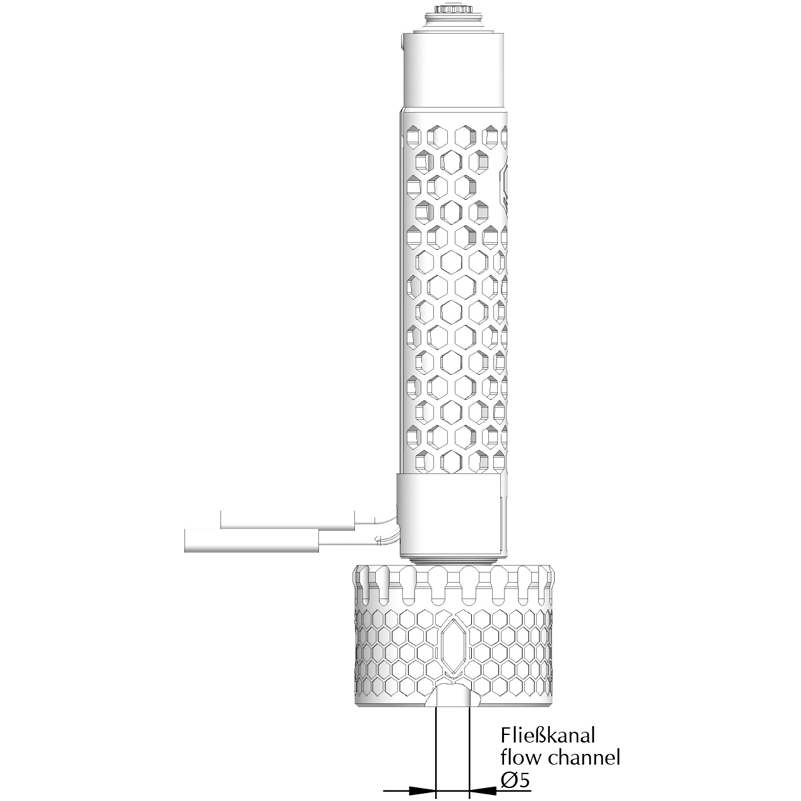

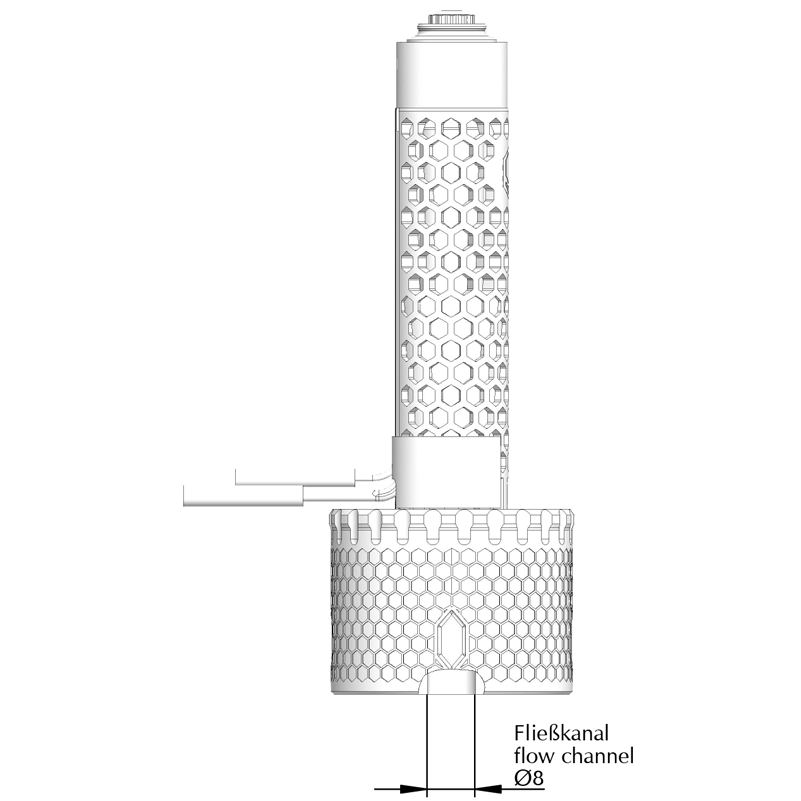

DB-24-R

DB-24-R

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

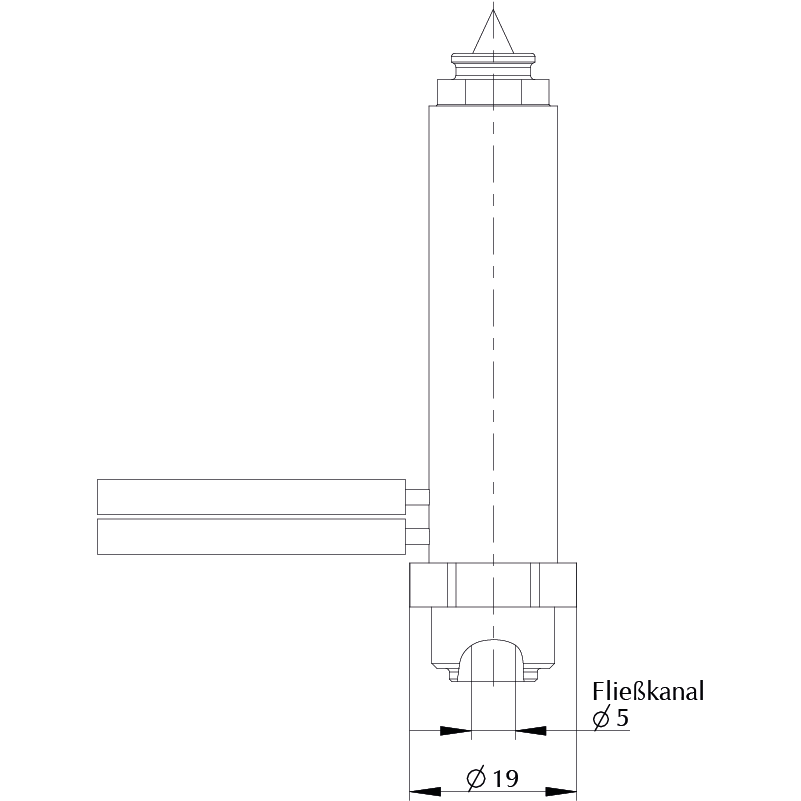

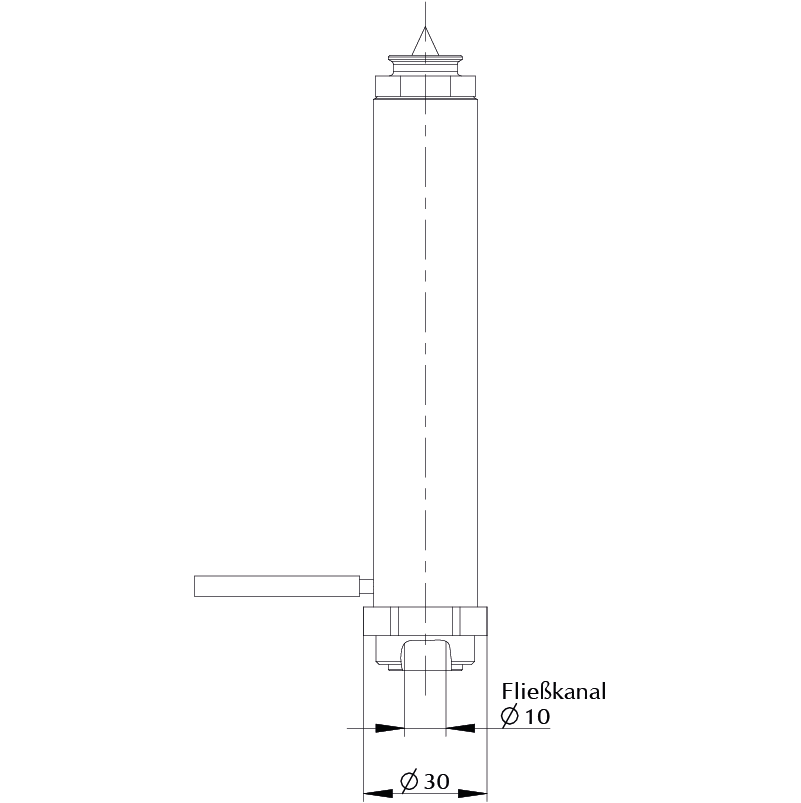

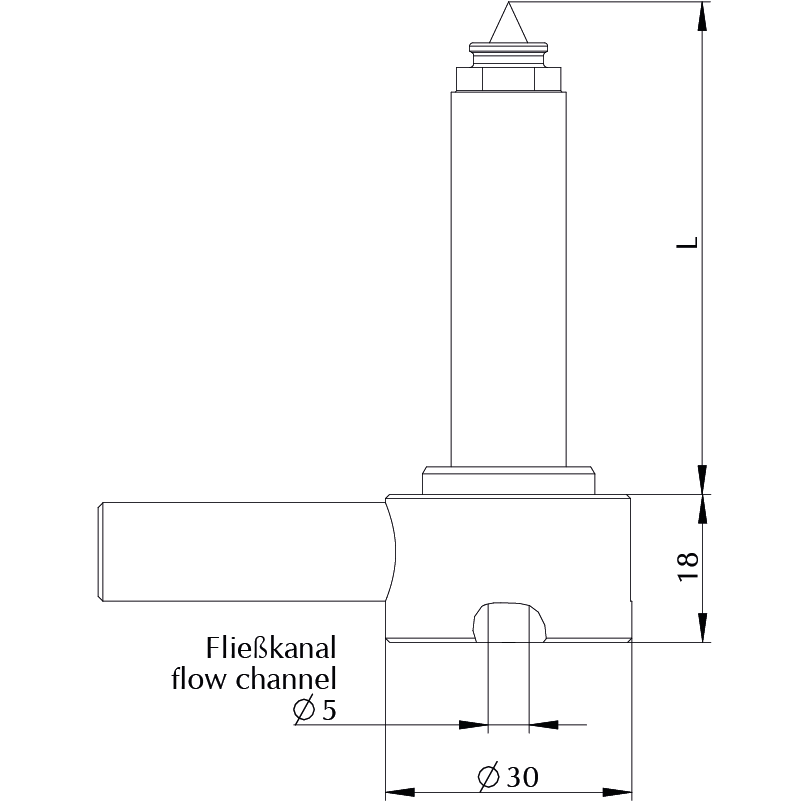

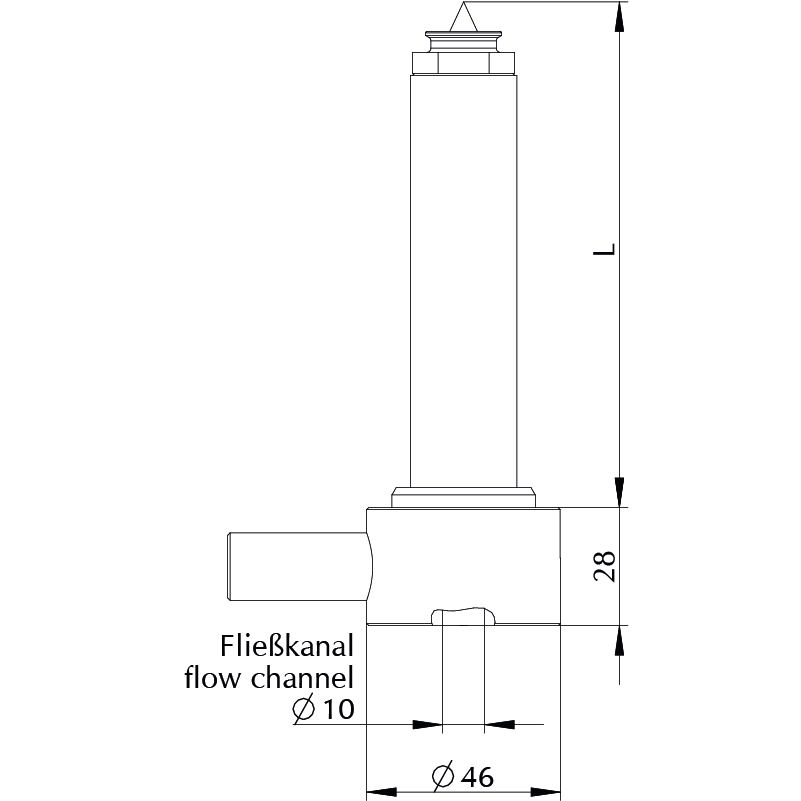

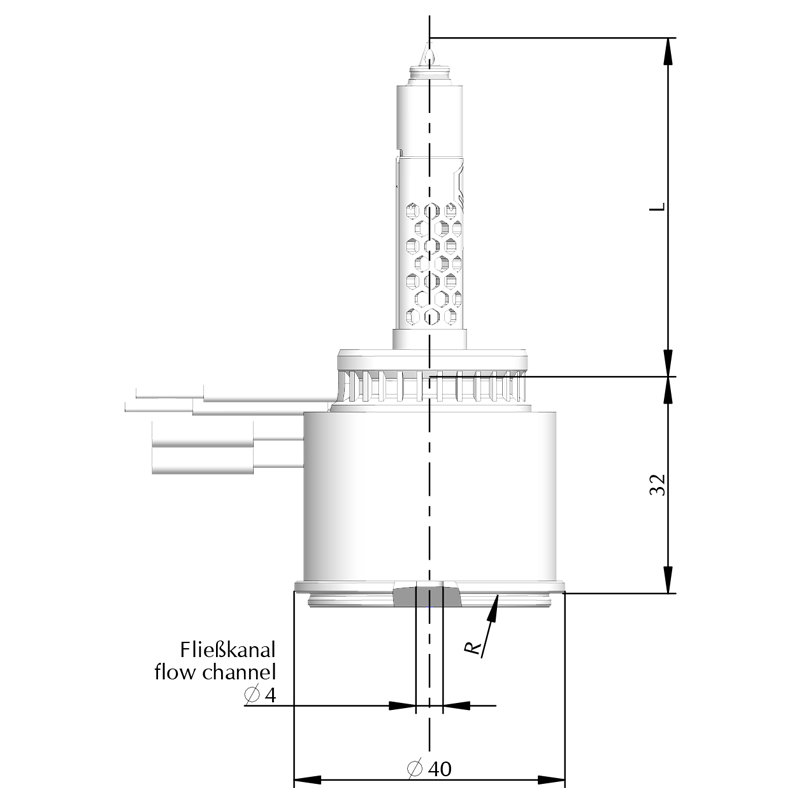

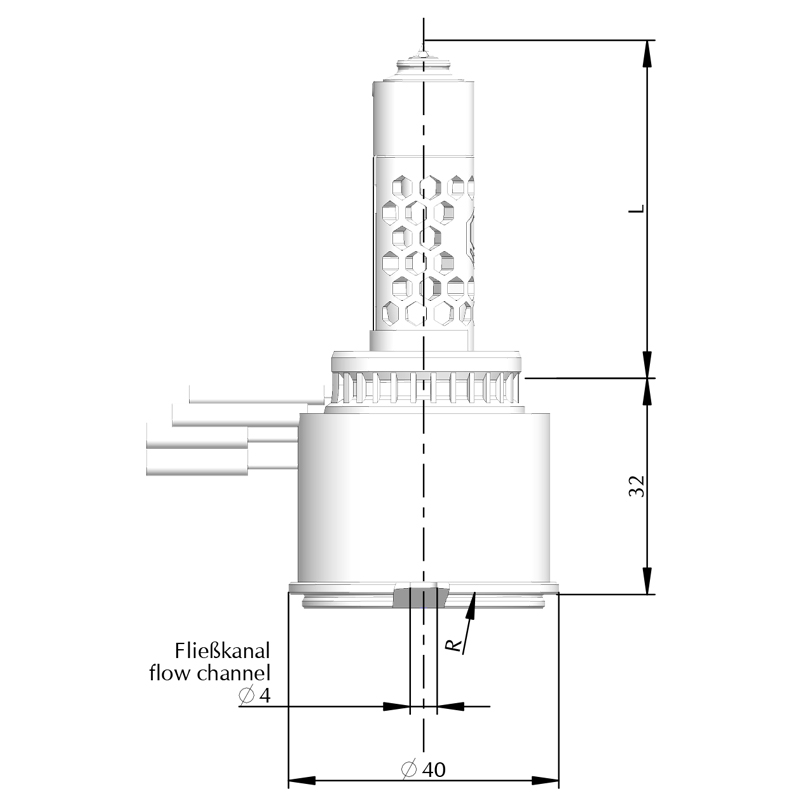

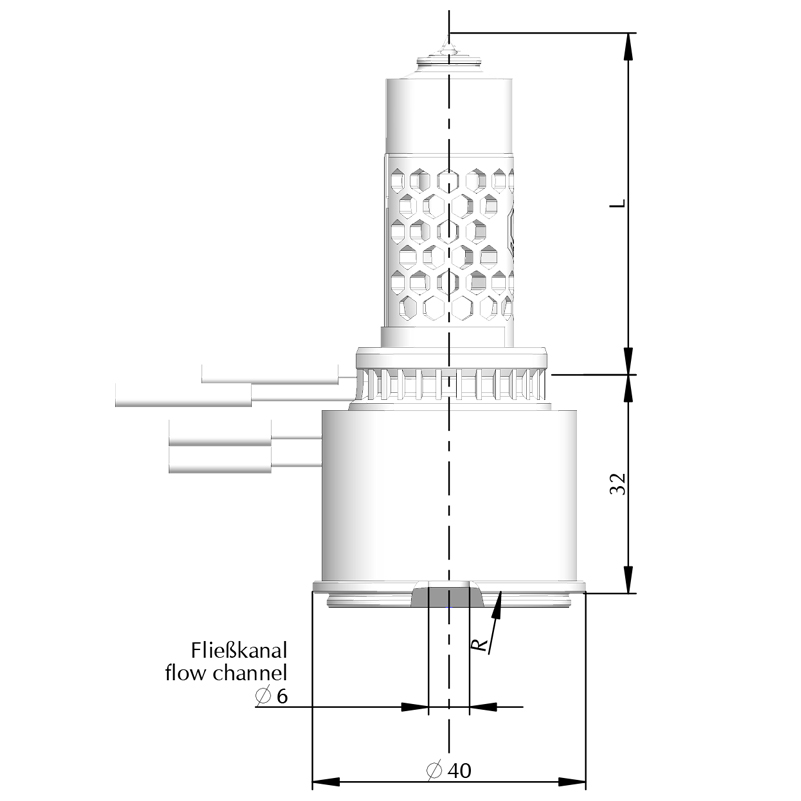

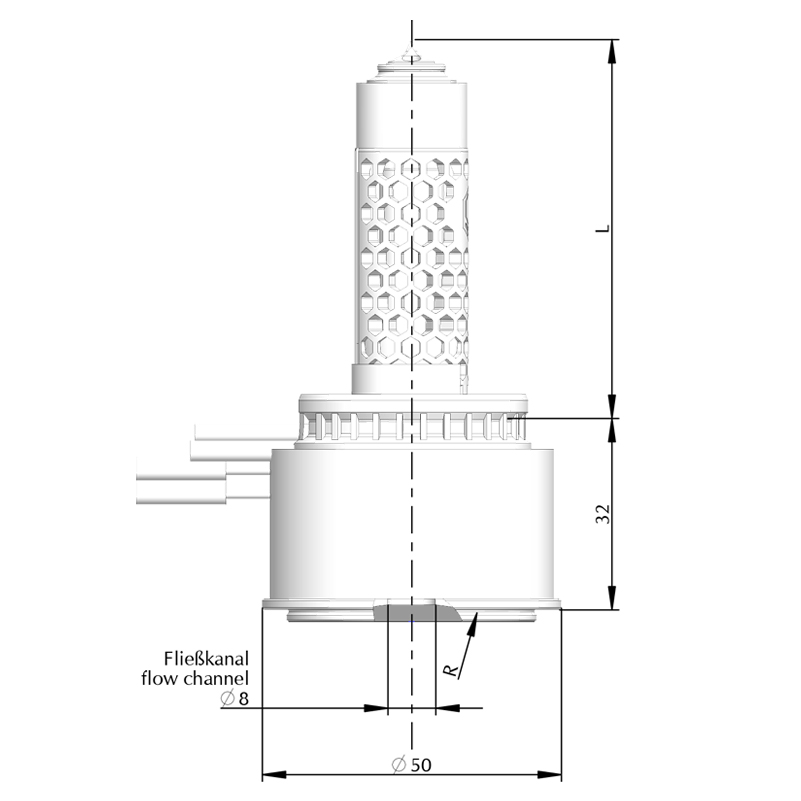

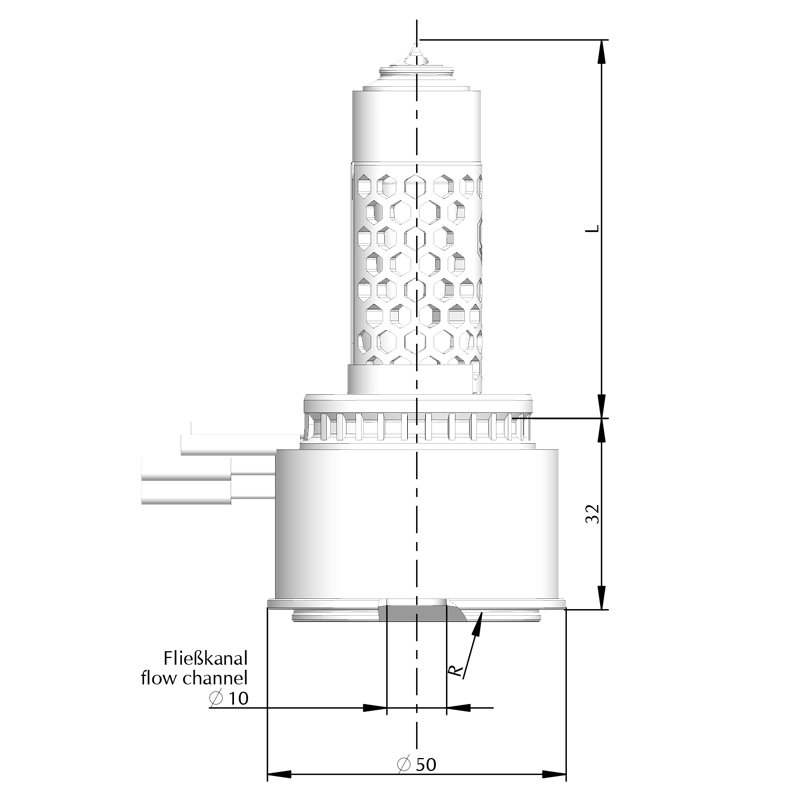

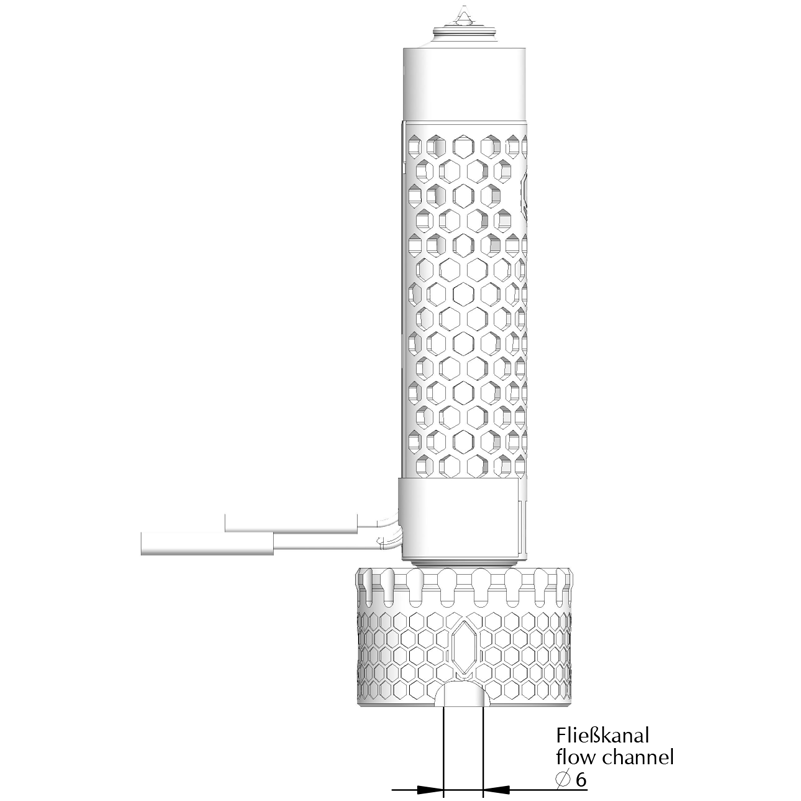

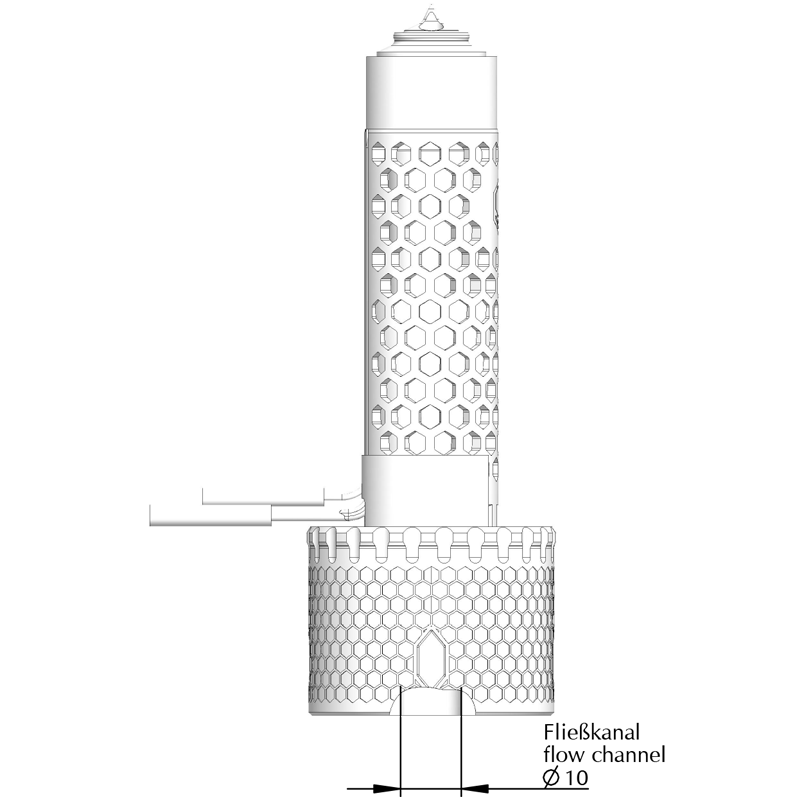

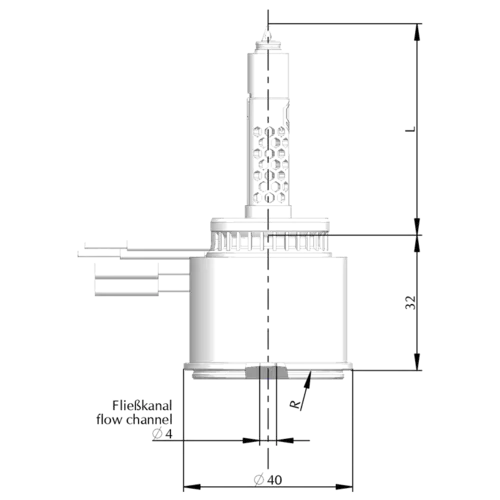

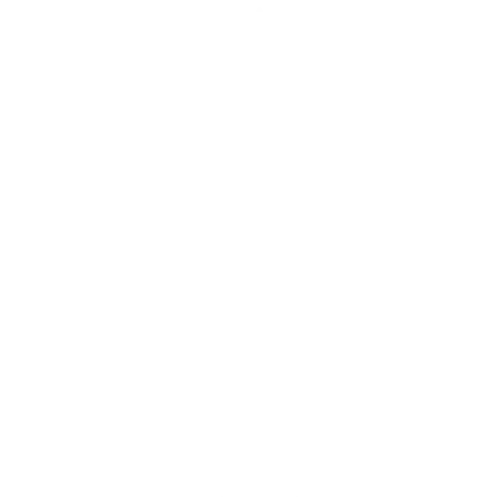

DB-32-R

DB-32-R

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

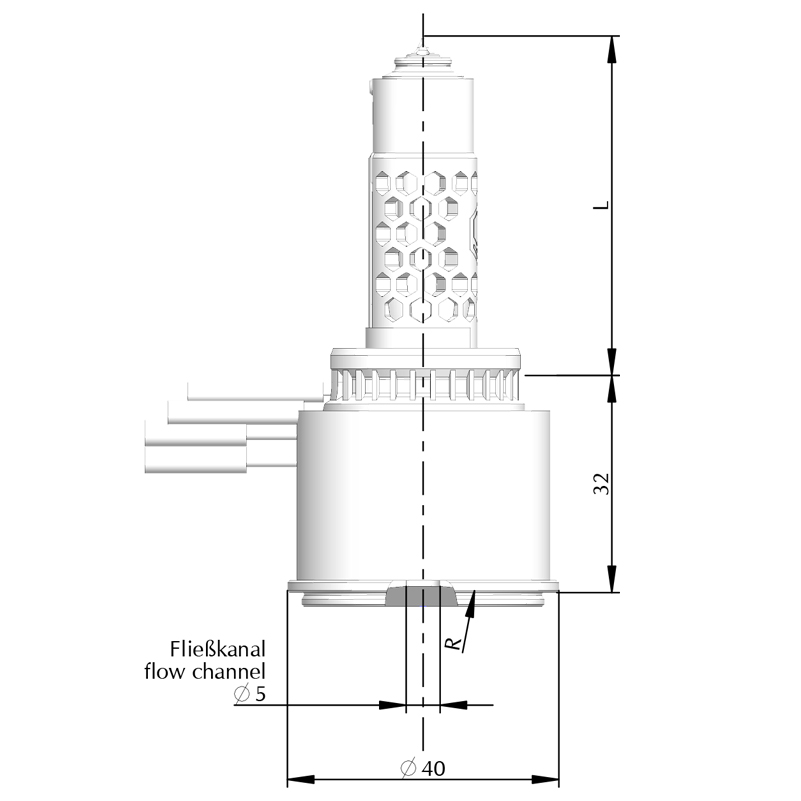

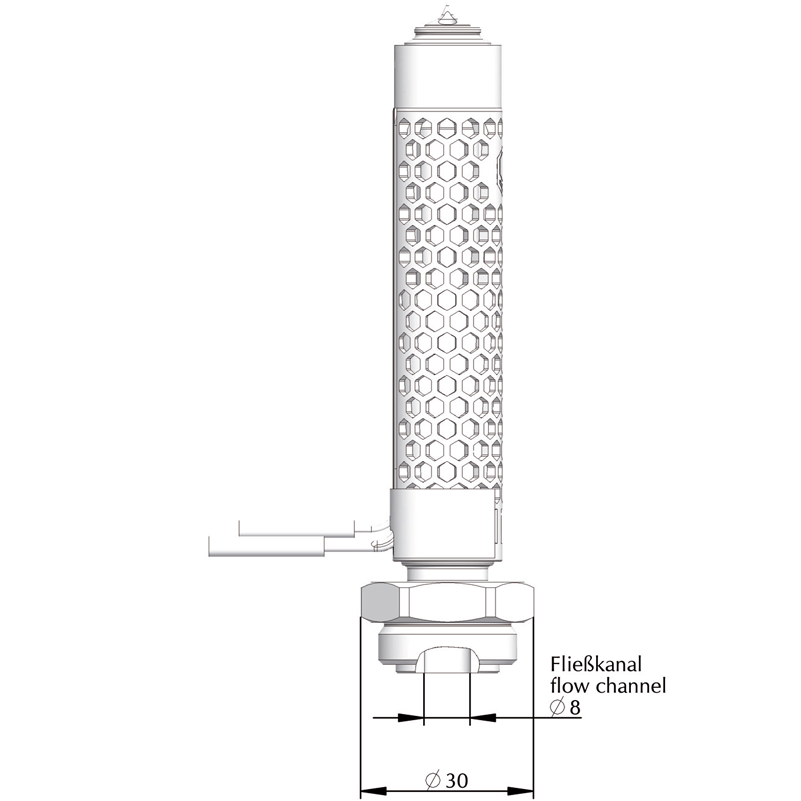

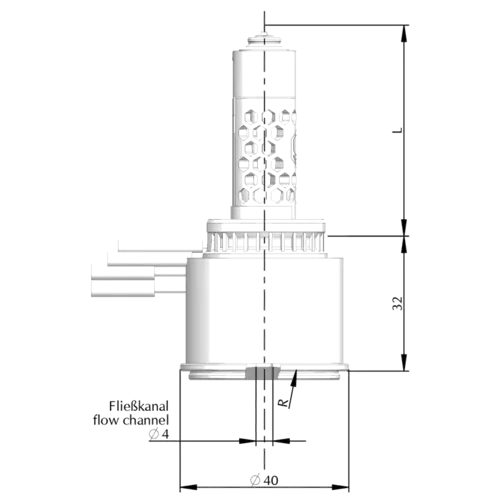

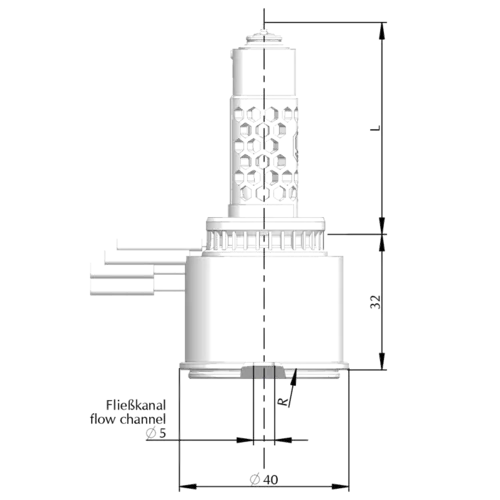

DB-40-R

DB-40-R

Single nozzle available in all tip variants.

Sealent type:

Tip seal / screwed-in melt chamber

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PCTA, PCTG, PETG, PCT, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

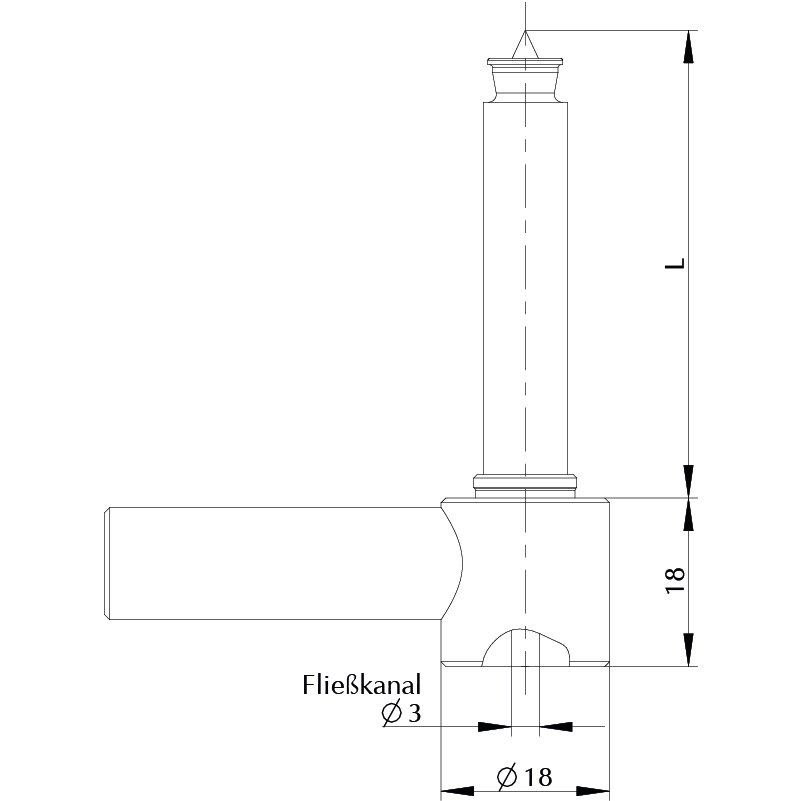

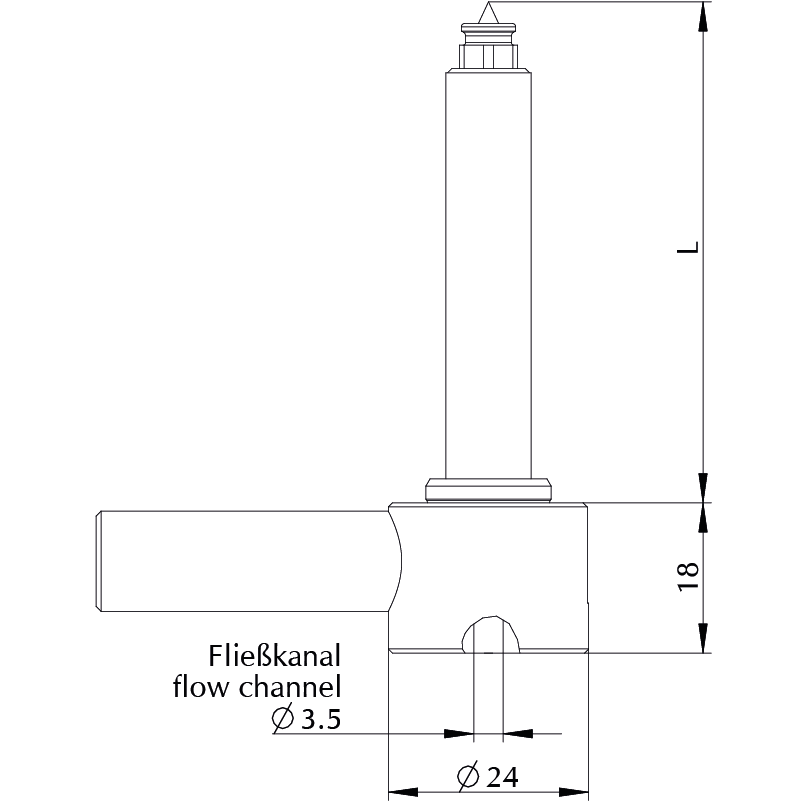

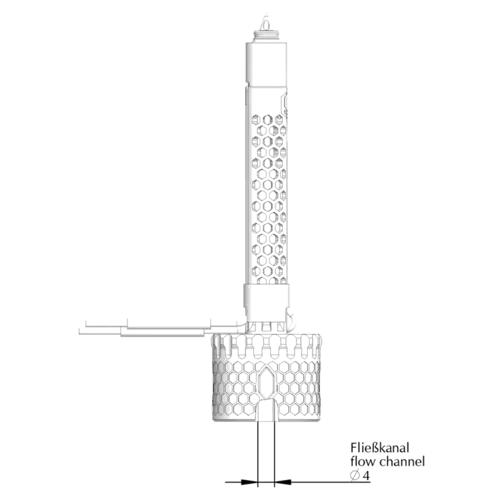

DE-10

DE-10

For use with manifold systems in cramped installation situations.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- tightest possible cavity

spacing = 11mm

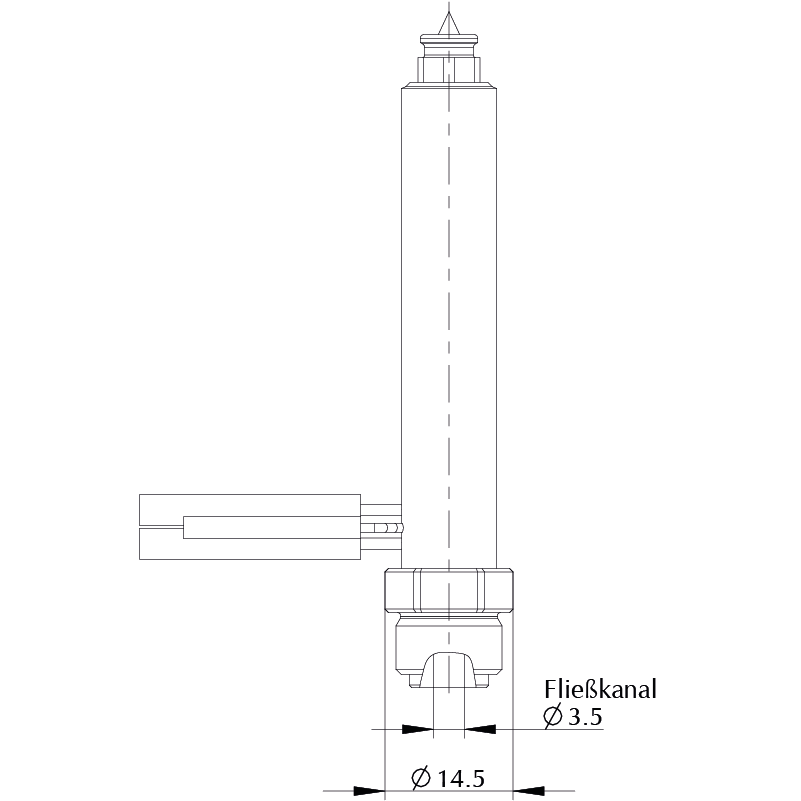

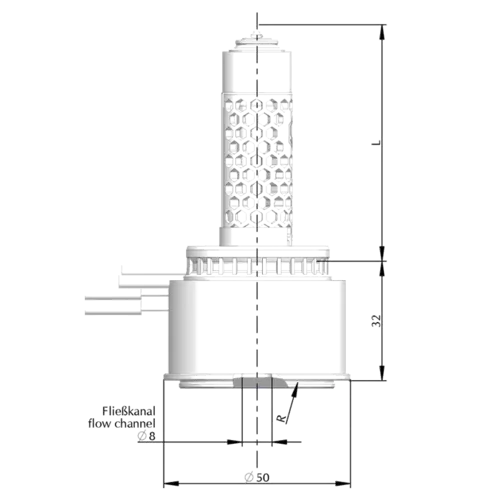

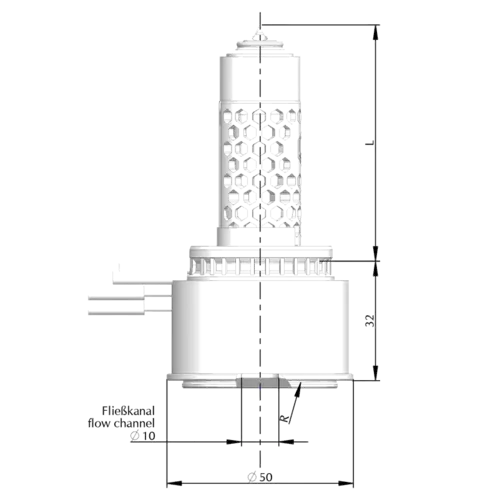

DE-6,7

DE-6,7

For use with manifold systems in cramped installation situations.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, POM, PP, PS, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m power cable

- cramped possible cavity

spacing = 8x13 mm

DS-14

DS-14

System nozzle available with all tip variants.

Sealent type:

Valve gate tip seal

Spitzentyp:

Torpedo, EVO-RS tip, through-hole tip, Open tip

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE,POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DS-14-N

DS-14-N

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE,POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

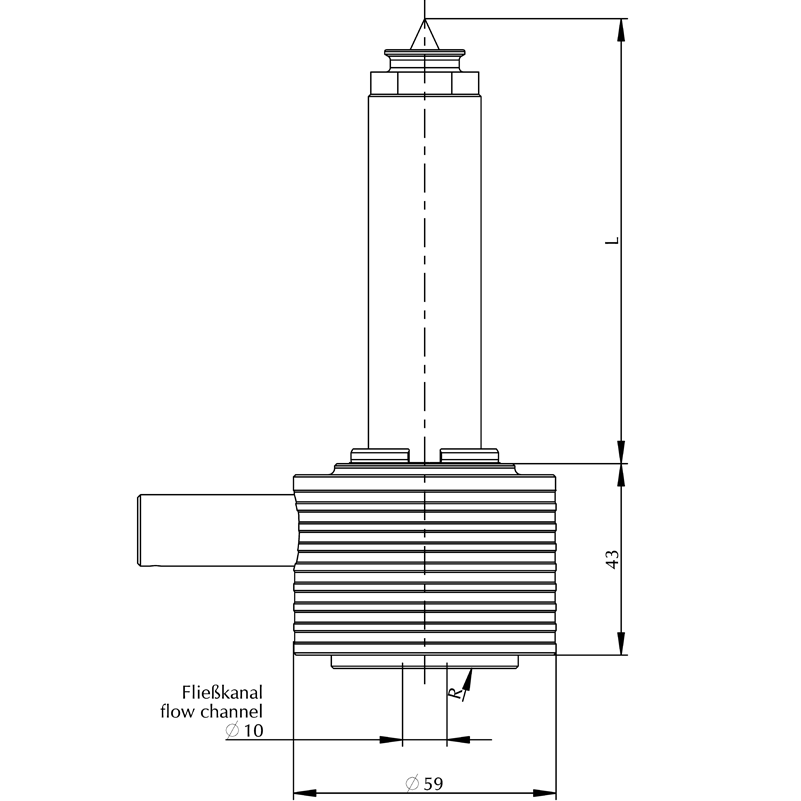

DS-16

DS-16

System nozzle available with all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

DS-16-N

DS-16-N

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PMMA, POM, PP, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

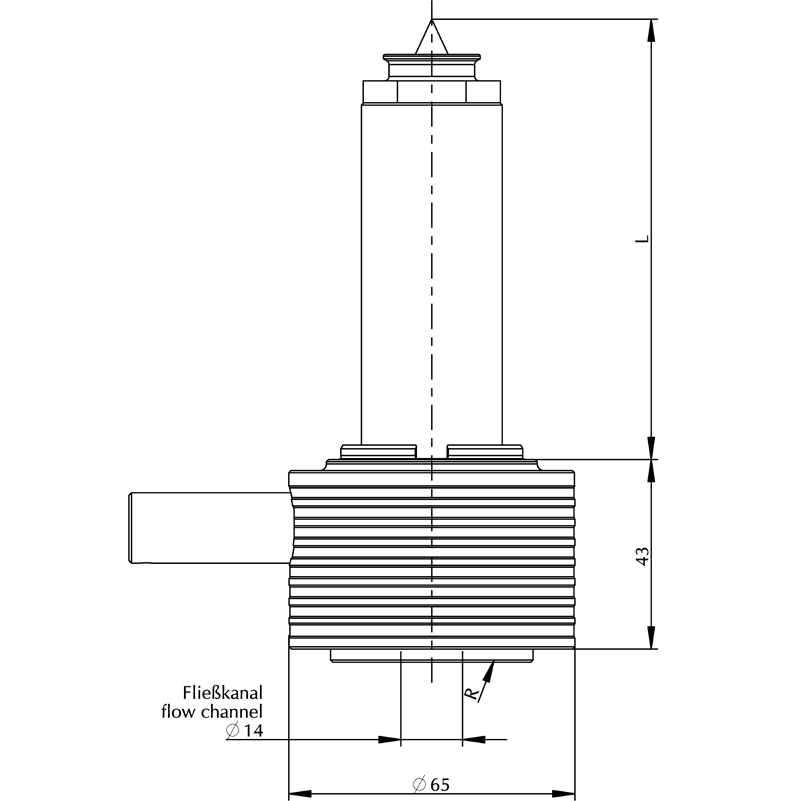

DS-20

DS-20

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS ,ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

DS-20-N

DS-20-N

System nozzle available in all tip variants.

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

DS-24

DS-24

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

DS-24-N

DS-24-N

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

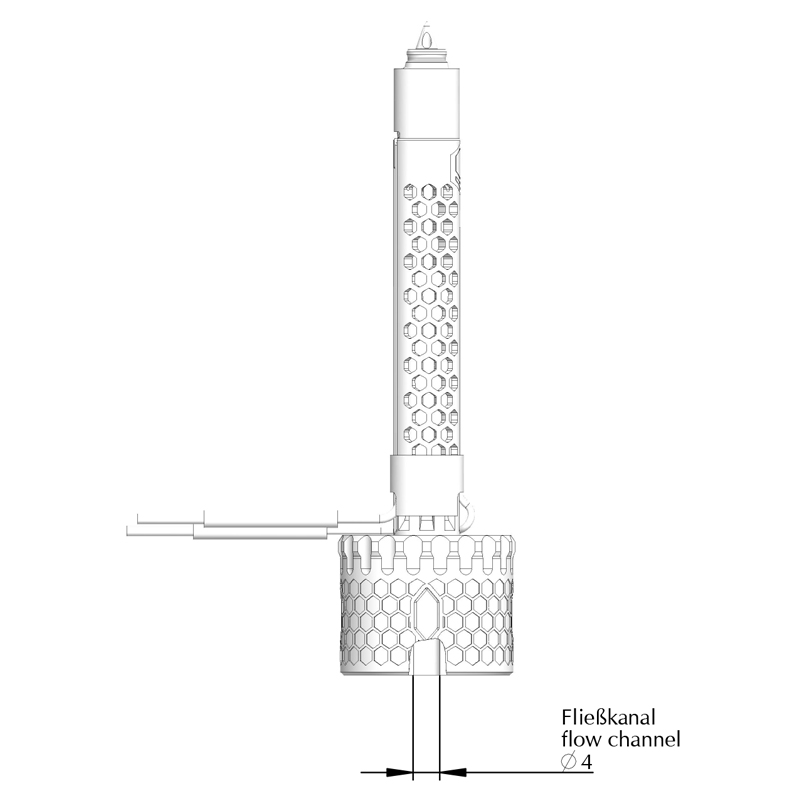

DS-32

DS-32

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

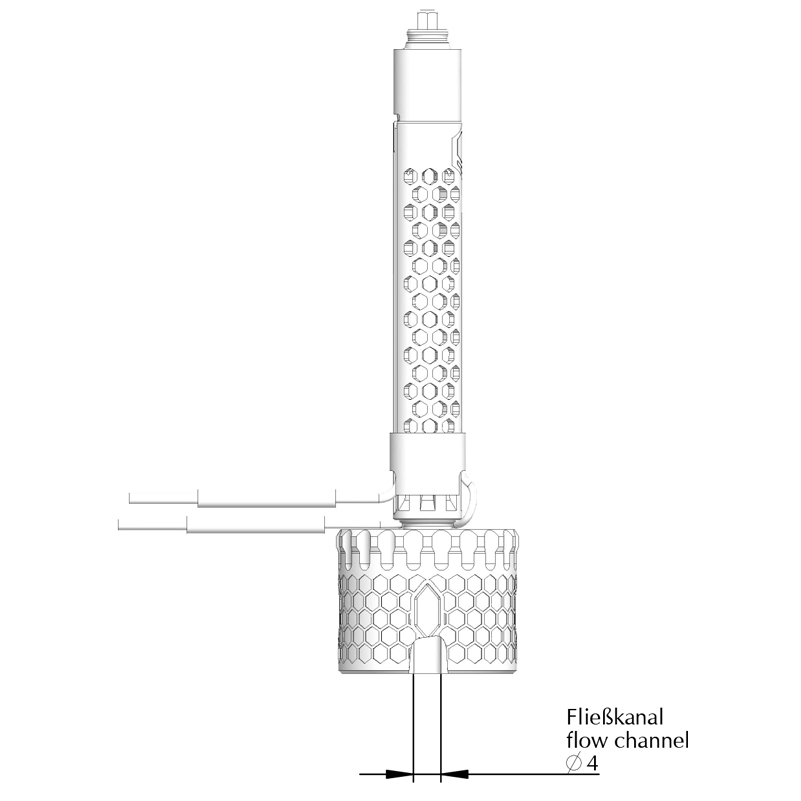

DS-32-N

DS-32-N

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

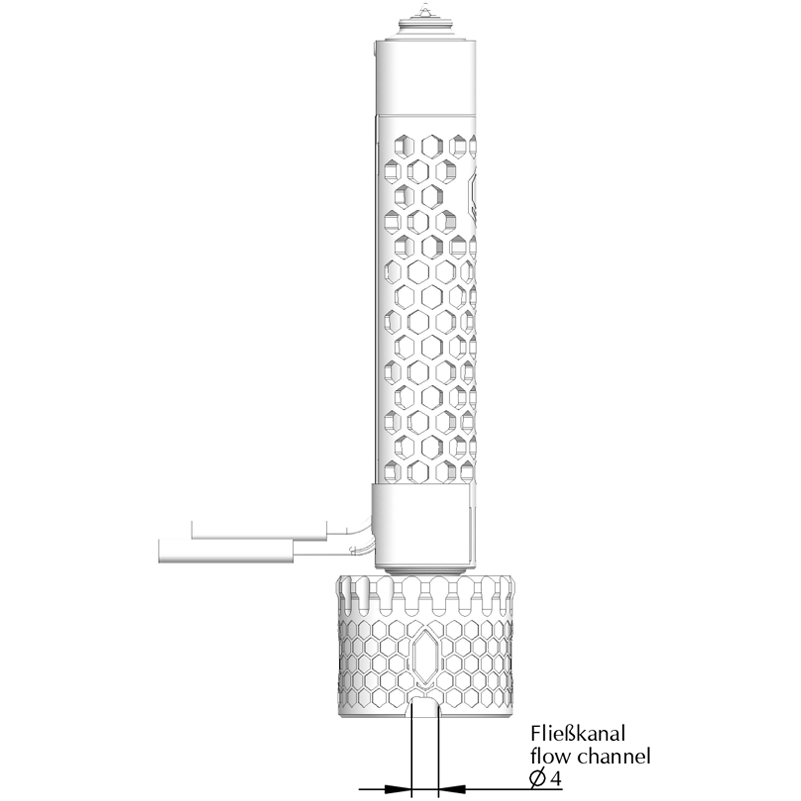

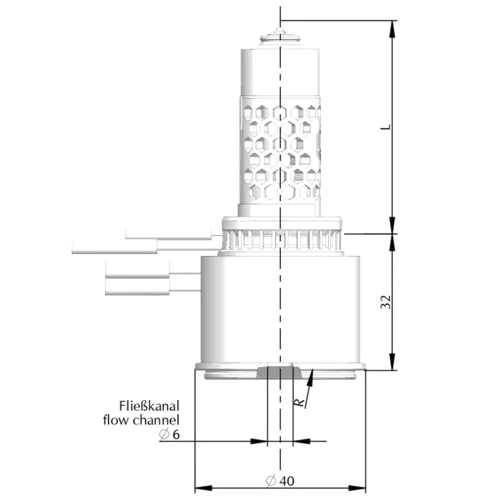

DS-40

DS-40

System nozzle available in all tip variants.

Sealent type:

Tip seal

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

DS-40-N

DS-40-N

System nozzle valve gate

Sealent type:

Valve gate tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

DT-11-B

DT-11-B

System nozzle available in many tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, PA6, PA6.6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

DT-14-B

DT-14-B

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

DT-14-NB

DT-14-NB

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, POM, PP, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DT-16-B

DT-16-B

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DT-16-NB

DT-16-NB

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PMMA, POM, PP, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DT-20-B

DT-20-B

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DT-20-NB

DT-20-NB

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DT-24-B

DT-24-B

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DT-24-NB

DT-24-NB

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN,SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DT-32-B

DT-32-B

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DT-32-NB

DT-32-NB

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- cramped possible cavity spacing = 12mm

Attention:

New O-rings should be used each time of disassembly.

DT-40-B

DT-40-B

System nozzle available in all tip variants.

Sealent type:

Tip seal / cramped installation

Nozzle tip:

Torpedo, EVO-RS tip, Through-hole tip, Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

DT-40-NB

DT-40-NB

System nozzle valve gate.

Sealent type:

Valve gate tip seal / cramped installation

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 160, 200, 240, 280, 320

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

Attention:

New O-rings should be used each time of disassembly.

MONOLITH-11

MONOLITH-11

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA4.6, PA 4.6 GF15, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

- general installation instructions for nozzle can be found in infocenter

MONOLITH-11-N

MONOLITH-11-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6 GF15, PA6 GF30, PA6.6, PA4.6, PBT, PBT GF15, PBT GF30, PC, PC/ABS, PE, PMMA, POM, PP, PP GF15, PP GF30, PPS, PPS + 40%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

- general installation instructions for nozzle can be found in infocenter

MONOLITH-11-R

MONOLITH-11-R

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA4.6, PA 4.6 GF15, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Maximum injection pressure: 2000bar

- Special lengths available on request

- Linear expansion of the nozzle is already considered for ΔT=200°C

- Contact force of the machine nozzle minimum 16kN / maximum 100 kN

- general installation instructions for nozzle can be found in infocenter

MONOLITH-16

MONOLITH-16

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-16-N

MONOLITH-16-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PMMA, POM, PP, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-16-R

MONOLITH-16-R

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA4.6, PA 4.6 GF15, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Maximum injection pressure: 2000bar

- Special lengths available on request

- Linear expansion of the nozzle is already considered for ΔT=200°C

- Contact force of the machine nozzle minimum 16kN / maximum 100 kN

- general installation instructions for nozzle can be found in infocenter

MONOLITH-20

MONOLITH-20

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-20-N

MONOLITH-20-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-20-R

MONOLITH-20-R

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Maximum injection pressure: 2000bar

- Special lengths available on request

- Linear expansion of the nozzle is already considered for ΔT=200°C

- Contact force of the machine nozzle minimum 16kN / maximum 100 kN

- general installation instructions for nozzle can be found in infocenter

MONOLITH-22

MONOLITH-22

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-22-N

MONOLITH-22-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-22-R

MONOLITH-22-R

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Maximum injection pressure: 2000bar

- Special lengths available on request

- Linear expansion of the nozzle is already considered for ΔT=200°C

- Contact force of the machine nozzle minimum 16kN / maximum 100 kN

- general installation instructions for nozzle can be found in infocenter

MONOLITH-24

MONOLITH-24

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-24-N

MONOLITH-24-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-24-R

MONOLITH-24-R

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Maximum injection pressure: 2000bar

- Special lengths available on request

- Linear expansion of the nozzle is already considered for ΔT=200°C

- Contact force of the machine nozzle minimum 36kN / maximum 100 kN

- general installation instructions for nozzle can be found in infocenter

MONOLITH-28

MONOLITH-28

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCTA, PETG, PCT, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-28-N

MONOLITH-28-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, LCP, PA6, PA6.6, PA4.6, PBT, PC, PC/ABS, PE, PET, PMMA, POM, PP, PPO, PPS, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-28-R

MONOLITH-28-R

Hot runner nozzle for single application.

Sealent type:

Tip seal

Nozzle tip:

open

Suitable materials:

ABS, ASA, Copolyester, LCP, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PA6.6, PA6.6 GF15, PA6.6 GF30, PA6.6 GF50, PA4.6, PA 4.6 GF15, PA4.6 GF30, PA4.6 GF50, PBT, PBT GF15, PBT GF30, PBT GF50, PC, PC/ABS, PE, PEEK, PET, PMMA, POM, PP, PP GF15, PP GF30, PPO, PPS, PPS + 40%, PPS + 60%, PPSU, PS, SAN, SB, TPE, TPU

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Single application

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Maximum injection pressure: 2000bar

- Special lengths available on request

- Linear expansion of the nozzle is already considered for ΔT=200°C

- Contact force of the machine nozzle minimum 36kN / maximum 100 kN

- general installation instructions for nozzle can be found in infocenter

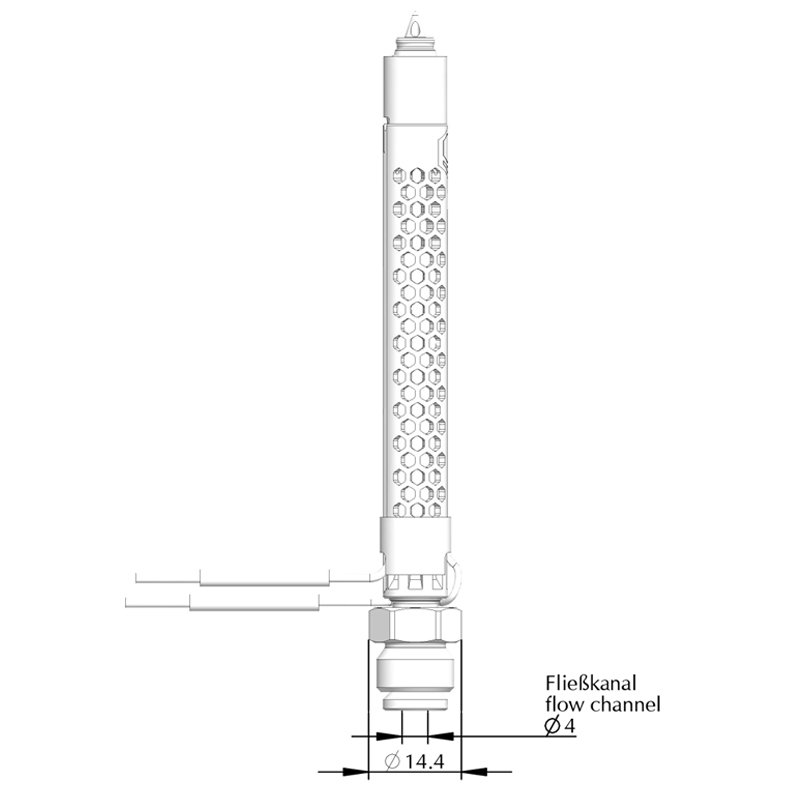

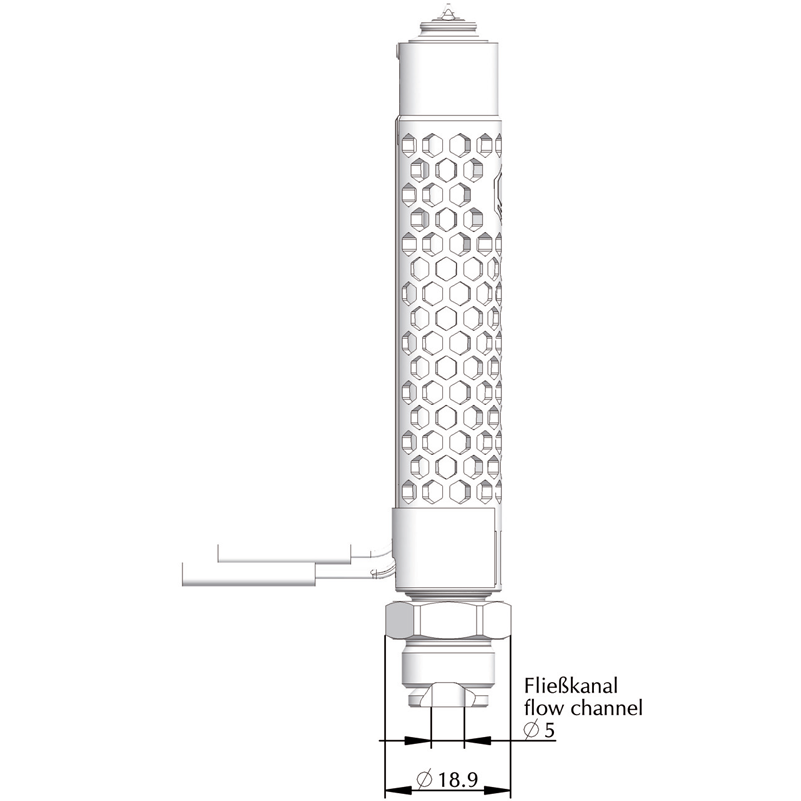

MONOLITH-FL-11

MONOLITH-FL-11

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PA6 GF15, PA6 GF30, PA6 GF50, PC, PC/ABS, PE, PMMA, PP, PP GF15, PP GF30, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

- general installation instructions for nozzle can be found in infocenter

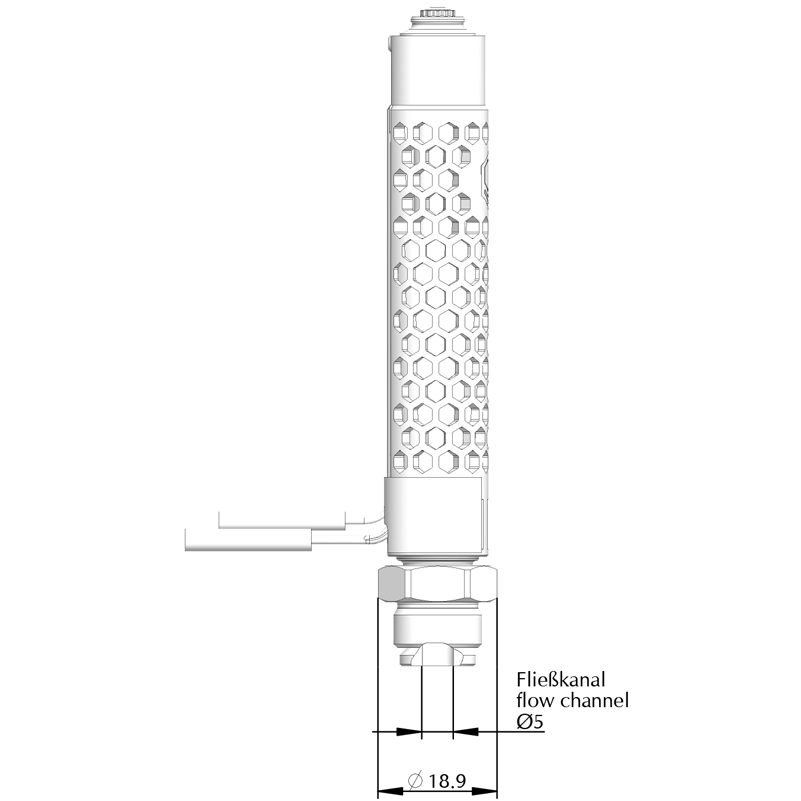

MONOLITH-FL-11-N

MONOLITH-FL-11-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PA6 GF15, PA6 GF30, PC, PC/ABS, PE, PMMA, PP, PP GF15, PP GF30, PPSU, PS, SAN, SB

Nozzle length (mm):

40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 220

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

- general installation instructions for nozzle can be found in infocenter

MONOLITH-FL-16

MONOLITH-FL-16

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-FL-16-N

MONOLITH-FL-16-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-FL-20

MONOLITH-FL-20

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-FL-20-N

MONOLITH-FL-20-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-FL-22

MONOLITH-FL-22

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCT, PCTA, PCTG, PETG, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-FL-22-N

MONOLITH-FL-22-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-FL-24

MONOLITH-FL-24

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PCT, PCTA, PCTG, PETG, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-FL-24-N

MONOLITH-FL-24-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

50, 60, 80, 100, 120, 140, 160, 180

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-FL-28

MONOLITH-FL-28

Can be used as open hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Open tip

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PEEK, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

MONOLITH-FL-28-N

MONOLITH-FL-28-N

Can be used as valve gate hot runner nozzle in conjunction with Witosa hot runner manifolds.

Sealent type:

Tip seal

Nozzle tip:

Valve gate

Suitable materials:

ABS, ASA, PA6, PC, PC/ABS, PE, PMMA, PP, PPO, PPSU, PS, SAN, SB

Nozzle length (mm):

60, 80, 100, 120, 140, 160, 180, 200, 240

Application:

Multiple applications (system application)

Note:

- incl. 1m power cable

- incl. 1m thermocouple cable

- Special lengths available on request

- DATA-DOWNLOAD

- +49 (0)561 12345